Table of Contents

Safety

The VP75 features state-of-the-art design and construction and has been built and tested with all necessary care so that it is safe to use under all circumstances. All legal safety requirements have been taken into account and it has been taken great care to fulfill the requirements of national and european law.

INFO

Regard that german legal standards apply. National and local laws and standards may be different. Always consider your local standards before setting up and operating the machine.

Nonetheless, hazardous situations may appear due to the production process itself.

False operation and/or handling of components can lead to intensive property damage; therefore we strongly recommend following the information given in this manual.

The risk of experiencing hazardous situations is increased by:

- Using the VP75 for other applications than the intended.

- Inappropriate use.

- Operating the machine in a non-safe state or under improper conditions.

- Insufficient attention, lax handling or intensive soiling.

Therefore:

- Use the VP75 for its intended use only.

- The VP75 must be in good working condition and in a safe state at any time. Check the machine prior to every commissioning and at regular intervals for wear, damage and cleanliness.

- Ensure that nobody can be injured by parts of the machine.

- Fix any error condition or visible damage immediately. If prompt rectification is impossible, decommission the machine and do not put it back to use unless all problems have been solved.

- Regard the local accident prevention regulation.

- Provide access to the operating manual for anybody operating the machine.

INFO

The manufacturer cannot be held liable for injuries and damages due to inappropriate use of the VP75.

Inappropriate use of the VP75 voids the manufacturer's warranty.

Safety equipment

The VP75 is equipped with safety devices to ensure safe handling. Additional safety eqipment can be installed if required.

It is forbidden to remove or deactivate safety equipment. The machine may only be operated with all safety equipment properly installed and in faultless condition.

Constructive safety

Due to the mechanical design, the VP75 provides safety to most hazards related to the machine itself and the additive manufacturing process.

The weight of the machine is evenly distributed over the installation area. In upright position the centre of gravity is below the machine centre, thus preventing toppling by vibration and normal application of force (e.g. closing the build chamber door). The adjustable feet provide optimal alignment and a stable stand.

All moveable and/or heated components are encapsuled and moving speeds do not exceed 250 mm/s. The build chamber door is magnetically kept close when shut.

The build chamber walls are insulated against thermal radiation with high temperature insulation foam. The outer surfaces do not exceed temperatures of 25°C. They are safe to the touch at any time.

The insulation keeps the sound level of the VP75 below 60 dB(A) during production.

Electrical safety

The supply voltage of the VP75 is 230 V(DC). It is partially reduced and distributed to 24 V and 12 V operating voltages by the power supply unit.

All current carrying parts are adequately isolated and encapsuled in the electronic compartments in the upper and lower service chamber of the machine.

To switch of current during normal operation, the machine is equipped with a main switch on the rear side.

Emergency stop

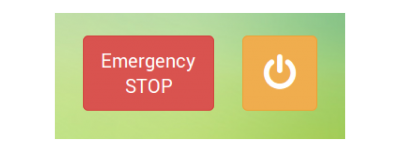

In the top-right corner of every screen of the operating system you will find a red Emergency STOP button. In case of any unexpected performance of the machine, press this button to immediately stop any mechanical movement in the build chamber and to shut down all heater elements.

NOTICE

The emergency stop function does not provide a cool down sequence. Do not use the emergency stop button to abort current manufacturing processes, because this may lead to damage of the machine due to uncontrolled heat accumulation.

Do not use the main switch as an emergency stop button. You risk loosing or corrupting data.

When the emergency stop is triggered, the microcontroller board responsible for the stepper motors, heaters and sensors is reset immediately and returns to idle state afterwards. Now it is safe to resolve any problems or defects in the build chamber.

The build chamber can then be reactivated via the [Print] menue.

Detailed information are provided in the Operating Manual.

Injury risks

Some hazards are design related and cannot be avoided by mere constructive measures. To avoid injuries it is necessary that the operator is aware of such situations and takes adequate care. The owner has to make sure that the safety precautions are observed.

The safety advices given in the following are meant to protect the operator of the VP75. It is the owner's responsibility to ensure that anybody working with or on the machine is familiar with this chapter and observes the given information.

Electrical safety

The VP75 is operated with 110 to 230 VDC. Touching current-carrying parts can be life-threatening and cause severe injuries.

- Only connect the machine in accordance with the specifications given in the data sheet.

- Works on the electrical equipment of the VP75 and on the power supply system may only be carried out by skilled electricians.

- Always disconnect the machine from the power supply by switching the main switch off and removing the mains plug from the socket before carrying out maintenance, repair or cleaning.

- Check the condition of cables and isolations at regular intervals and replace damaged parts immediately.

- Do not setup and operate the machine in a humid environment.

Hot surfaces

Inside the build chamber, the heating element generates the necessary ambient temperature set for a specific material. Depending on the processed material, surfaces inside the build chamber can reach temperatures up to +80°C.

The build plate is heated separately. It can reach temperatures up to 150°C.

The extruder nozzle is heated to melt the filament strand and may exceed temperatures of 500°C.

Do not open the build chamber during or immediately after completion of a print job. The build plate heating shuts down after finishing a print and cools down to chamber temperature. Always wait at least 10 minutes before removing the printed object. This is also to avoid stress cracks due to sudden temperature drop.

If, for reasons of avoiding damage (e.g. collisions), it becomes necessary to interrupt the printing process and to open the build chamber before the cool down time has passed, wear adequate protective gloves when touching any internal parts.

Noise

The sound level of the VP75 does not exceed 60 dB(A) during production. Hearing protection is not required.

The machine is not suited for workplaces with high requirements regarding acoustic disturbances (e.g. offices). It can be set up

Organisational safety measures

Operator qualification

Operating and service personnel must be familiar with the information provided in this manual. Special training and qualification are not required for operating the machine. Works on the electrical equipment and connections require profound knowledge of electrics and electronics.

Personal protective equipment

During normal operation it is not necessary to wear special protective gear. Some tasks however should not be performed without taking protective measures. Situations that require protective equipment are specially indicated. It is the owner's obligation to provide adequate protective equipment.