This is an old revision of the document!

Quick Start Guide

Congratulation, you seemingly just received your RepRap Industrial 3D Printer. Read the following instructions thoroughly and you are up and running in no time.

You will always find the latest version of the manual, additional documentation and new software releases at

Please visit our site regularly so that you do not miss important developments and new features.

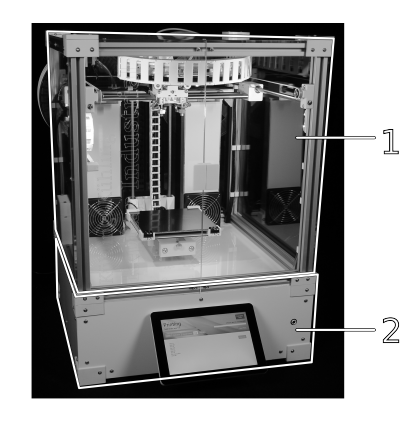

Components overview

| No. | Description |

|---|---|

| 1 | Build chamber |

| 2 | Electronic chamber |

| No. | Description |

|---|---|

| 3 | Operating screen |

| 4 | Wake button |

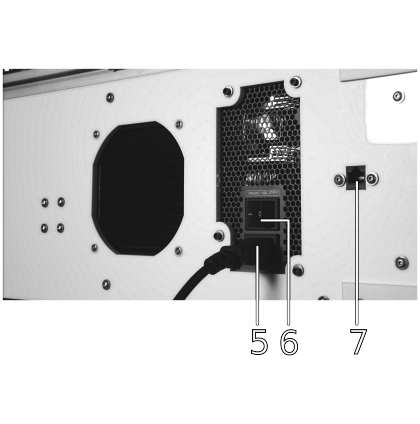

| No. | Description |

|---|---|

| 5 | Mains socket |

| 6 | Main switch |

| 7 | RJ45 ethernet socket |

| No. | Description |

|---|---|

| 8 | Filament inlet with limit switches |

| 9 | Filament spool carrier |

| 10 | Filament spool |

Safety precautions

ELECTRICAL HAZARD!

All electrical equipment inside the 3D Printer has been designed and built in accordance with the regulations stated in the Low Voltage Directive 2006/95/EG (see Declaration of Conformity) and established electrical engineering practice with all necessary respect to the user's safety.

Regard that handling electrical equipment always implies risks that require special care.

To avoid electrical shock and burning injuries and damage to the 3D Printer:

- Only connect the 3D Printer to the specified supply voltage.

- Do not operate the 3D Printer with defective cable connections.

- Do not set up the 3D Printer in a moist environment.

DANGER OF CUTTING INJURIES AND EYE DAMAGE!

The packing straps are pretensioned and may whip when cut, causing cutting injuries or eye damage.

- Hold down the top part of the strap and cut it at the side. Make sure it does not hit somebodies face.

DANGER OF CRUSHING!

The 3D Printer weighs 50kg (empty). Dropping or toppling of the 3D Printer may cause crushing injuries. Lifting the printer on yourself can cause back injuries.

- Always carry the 3D Printer two by two and hold it from beneath the bottom edges.

DANGER OF CUTTING!

The transport box is made of unfinished plywood and may hold splinters and sharp edges that can cause cutting injuries.

- Take care when removing the transport packaging and wear protective gloves.

NOTE

If the 3D Printer has a temperature below 16°C (e.g. directly after delivery in cold weather) there is a danger of air humidity condensing on sensitive electronic components. This can lead to severe damages due to short circuiting during commissioning.

Therefore, it is necessary to let the 3D Printer warm up to ambient temperature at its operating place prior to commissioning.

Regard the ambient conditions required for operation.

NOTICE

In order to ensure your own safety and the proper functioning of your RepRap Industrial during operation read and observe the safety instructions in the online documentation.

Installation requirements

- For optimal operation a free space according to the adjacent picture should be provided.

- The substructure of the 3D Printer must be stable and weight carrying with a minimum payload of 60kg and a flat surface.

- No tablecloth must be placed underneath the 3D Printer to avoid blocking the ventilation openings in the bottom. Loss of air flow can lead to severe damage by overheating of the drives.

- The 3D Printer must not be set up in a surrounding with high formation of dust (e.g. near woodworks, grinding workplaces etc.). Ingress of particles into the filament feed system can lead to intense cleaning efforts due to clogging of the nozzle tips and thus immense non-productive time.

- Also ensure that the 3D Printer cannot topple, slide or tilt due to operating vibrations.

- A 110 - 230 V(AC) power source must be within reach of the power cable (1 m).

- Your network must provide DHCP IP address management and should be connected to the internet to enable the 3D Printer to fetch current time signal via Network Time Protocol (ntp).

Refer to the online manual if your network is built differently.

Setup

- Cut and remove the packing straps around the transport box.

- Open the wooden transport box's lid and lift the plywood frame off the pallet in one piece.

- Cut and remove the packing straps around the 3D Printer.

- Remove the wooden panel and foam wrap on top of the 3D Printer.

- Take out the accessory kit box.

- Lift the 3D Printer onto the prepared pedestal.

- Remove all transport securing devices (blue tape and the cardboard underneath the print bed).

- Check the entire device carefully for any transportation damage and completeness of delivery.

Connecting, turning on and accessing the 3D Printer

- Plug the mains cable into the mains socket at the rear cover and connect the 3D Printer to the power supply.

- Connect the 3D Printer to the local network via the RJ45 plug at the rear cover.

- Toggle the main switch at the rear cover to <I> (ON).

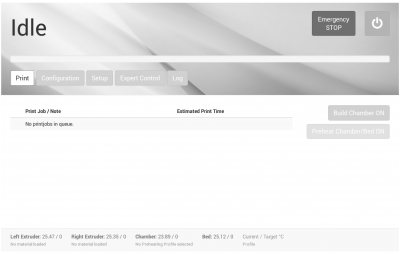

- It may take a few minutes until the touchscreen has fully loaded the operating screen - wait patiently without interfering. The first screen will be the Print screen with the (empty) print-job queue and the top-left status message displaying Idle.

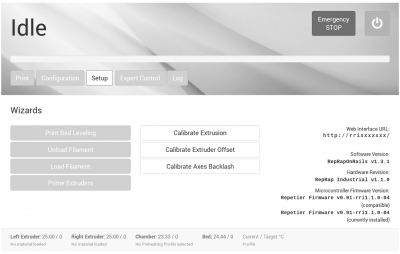

- Switch to the Setup tab via the respective button in the header.

- Write down the web-interface URL displayed on the right half of the screen.

- Now open your web browser on your PC and enter the web-interface URL in the address line. You will be greeted with the First steps screen that provides a direct link to the online manual where all steps next to be taken are explained in detail.

If you encounter problems with accessing the 3D Printer (or anything else) you may find help in the Troubleshooting section of the online manual

(http://docs.kuehlingkuehling.de/reprap-industrial-v1/troubleshooting).

That's it - your RepRap Industrial 3D Printer is ready for the first print.

Proceed with the instructions provided in the online documentation to perform your first prints and familiarize with your 3D Printer.