This is an old revision of the document!

Description

The following paragraphs name and explain all components of the VP75 to give you an exact overview. The terms are used consistently throughout this manual and will help you identifying any part you may wish to find or order as a spare part.

Functional principle

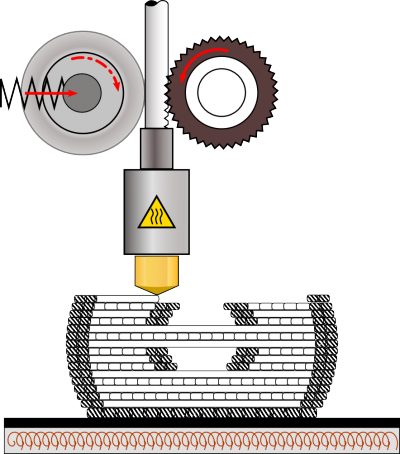

The VP75 Additive Manufacturing System uses the Fused Filament Fabrication (FFF) process to build up workpieces in subsequent layers of 0.10 to 0.80mm thickness. The plastic filament is heated in the nozzle to its melting temperature and continuously conveyed by a cogwheel. The molten plastic is pressed through the bore of the nozzle tip and onto the heated print bed. After each layer the print bed is lowered by the preset layer height and the next layer is applied. The heat of the newly applied plastic ensures an adequate binding of the layers.

All temperatures and movement commands are provided by the GCODE, a file format previously generated with a “slicing” software. This file contains all information for a single print job and is uploaded to the 3D Printer via the web interface. All Kühling&Kühling 3D Printers are built to operate best with Slic3r, an OpenSource Software designed for professional 3D printing.

After the workpiece has been finished the user can leave it in the heated build chamber to slowly cool down thus reducing shrinkage and internal tensions, or he can immediately remove it and start the next print job.

The layered building process enables the user to create even complex forms that otherwise could not be realized.