This is an old revision of the document!

Table of Contents

Tips & Tricks

General

Here you will find information about general issues concerning the operation of the RepRap Industrial in your specific work environment.

Setting a static IP address for RepRap Industrial ethernet connection

Use SSH on your computer connected to the same LAN as your 3D printer to log in to the RepRap Industrials' built-in BeagleBone Black. Enter the printers' Backend-URL and log in with the following access data:

User: kiosk Password: eight-digit combination from the serial number at the back of the device. Take the first two four-digit blocks - XX-AAAA-BBBB-CCCC-YYYY becomes an "AAAABBBB" password.

Edit the network configuration via the command line editor “nano”

sudo nano /etc/network/interfaces (use the above user and password)

The current DHCP setup looks like:

# The primary network interface auto eth0 iface eth0 inet dhcp pre-up iptables-restore </etc/iptables.rules

Change the setup according to your needs.

Example:

# The primary network interface

auto eth0

iface eth0 inet static

address 192.168.1.20

netmask 255.255.2555.0

network 192.468.1.0

broadcast 192.168.1.255

gateway 192.168.1.254

dns-search family.local

dns-nameservers 192.168.1.254

pre-up iptables-restore </etc/iptables.rules

The rest of the file remains unchanged. Save the file using CTRL+X and confirm the overwrite query with “Y”. Disconnect and finish by typing

exit

Shut down (see Manual control) and reboot (power-on button, 11 in fig. 4) the RepRap Industrial to establish the alterations.

Filament quality check

Much to our regret, filament manufacturing is not subject to standardization yet. Although we try to provide material of high quality and stable dimensions, manufacturing faults cannot be totally excluded.

If you order filament of other suppliers, please check back that it is within the stated tolerances. Some manufacturers offer a nominal “3 mm” filament which really is 2.85 mm in diameter, while others indeed sell 3.00 mm.

If you note that material purchased via Kühling&Kühling does not meet the standards we set here, please let us know and we will promptly replace the material. We only ask you to send back the flawed material (return note will be included in the new delivery) so that we can discuss the matter with our supplier.

If you experience increased problems with grinding at the drive gear, first thing to check is the quality of the filament currently loaded:

- Is the diameter correct?

- Is the filament round?

- Is the filament free of bulges and kinks?

INFO

To make sure that there is no problem in the filament feed system, try the following:

• Remove the filament feed hose from the filament inlet (push the blue fixing ring and pull the hose out).

• Feed the filament directly through the hose and try printing.

If the problem remains, check the filament as described.

Refit the hose afterwards!

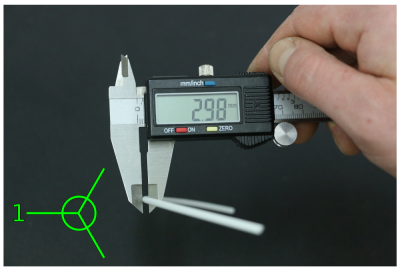

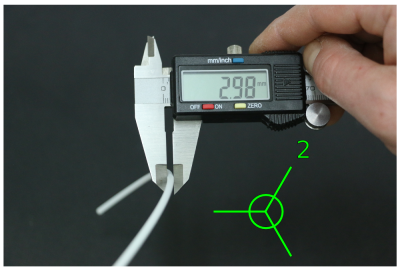

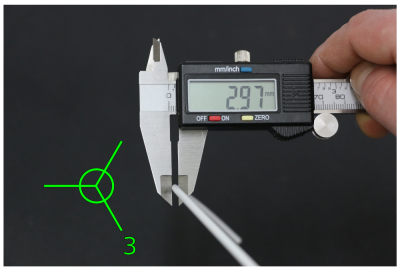

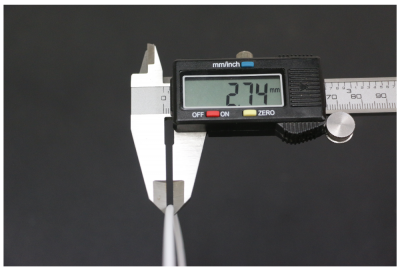

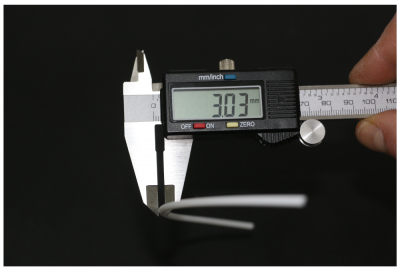

Diameter

Measure the diameter at several points (at least 5 per 0.5 m).

Measure at least twice (best thrice) at each point at an angle of 90° (60°).

The diameter must not deviate from

2.85±0.1 mm (2.75 … 2.95 mm)

A diameter of e.g. 2.98 mm will increase friction in the filament feed system and the nozzle barrel and cause compression and jamming of the filament.

A diameter of 3.00 mm will no longer fit through the filament feed inlet.

Filament below 2.75 mm is, especially when a print job requires a lot of retraction movement, likely to jam the nozzle barrel because molten filament can push itself back up the barrel and form a plug.

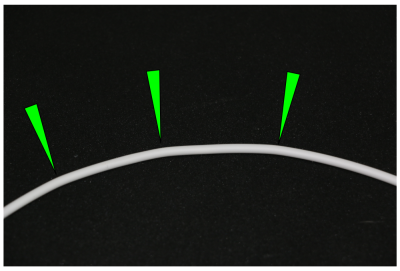

Roundness

Measure two times at the same point.

If one diameter deviates from the stated tolerance or if both diameters differ strongly, the filament is out of round and must be replaced.

Out of round filament, even when meeting the admissible values, is likely to form a plug inside the nozzle barrel because molten filament can push itself back up past the main strand.

Slicing

Any information we gather related to improving or easing the slicing process is listed in the following paragraphs.

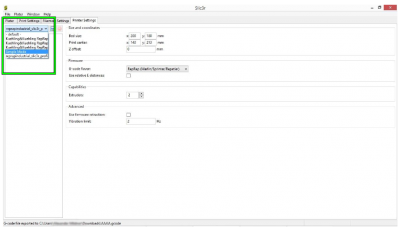

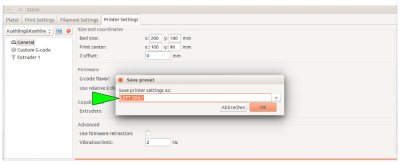

Profile display problems in Slic3r for Windows

This bug will be fixed with the upcoming release of SLic3r v1.2.x.

It is a known problem that in Slic3r for Windows the drop-down lists for the profile selection are too narrow to display the full profile name. This can make it impossible to choose the correct profile when processing your slicing settings for creating a G-code.

Try the following to bypass the problem:

- Select a profile from the drop-down list and click the <save> symbol.

This way, you make the profile name visible and editable.

- Delete the current profile name and replace it with a short description, e.g. “LEFT ONLY” instead of “Kuehling&Kuehling RepRap Industrial - LEFT EXTRUDER ONLY”.

Overhang - adjusting the layer thickness

If you want to print filigree objects with overhanging structures without adding supports, try reducing the layer thickness for this print by 15 - 20%. This will result in a finer Z-axis resolution and increased overlay of subsequent layers so that more stability is gained over the height of the target object.

First layer

The adhesion of the first layer to the print bed is extremely important to minimize warping (see this article also).

To optimize the adhesion, some Slic3r settings should be adjusted.

INFO

The following applies to the nozzle tip size 0.35 mm and the preset Slic3r profiles you installed during initial commissioning. It is meant to give you an overview of the settings relevant for the optimization of the first layer adhesion. Please experiment to find the settings best suited for your task and test all settings before applying them to your final model if you use other nozzle sizes.

- Set the layer thickness of the first layer (“First layer height”) to a value equaling the diameter of the nozzle tip bore and

- increase the extrusion width to 150 %.

Both measures compensate for unevennesses of the print bed and increase the tolerance against slight leveling mistakes. The distance between nozzle tip and print bed will assure that the bore is not clogged when passing convex bumps by leaving enough free space in between. The extrusion width will make sure that enough material is conveyed to equalize concave crudities.

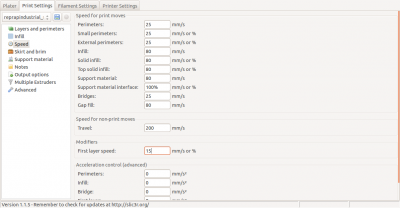

- Make sure that the first layer extrusion speed does not exceed 25 mm/s

(less for nozzle tips ≤0.35 mm).

Due to the higher heat transfer and the less sudden cooling the adhesion is increased.

- Optimize the extrusion and print bed temperature for the filament currently installed.

Do not hesitate to try different settings here, since even colored additives may alter the optimal extrusion temperature.

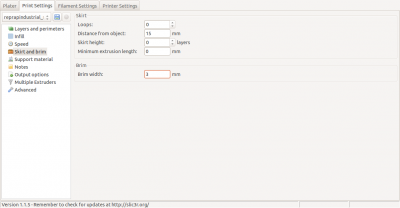

- For filigree or thin-walled objects add a 3 to 6 mm brim and/or 3 to 8 raft layers to increase the effective adhering area (see Slic3r manual also).

Modifying infill and perimeters

There are currently two Slic3r profiles available at our GitHub repository that provide preset ready-to-print slicing settings. Her are some tips for handling these profiles to adjust them to your needs.

The SOLID profile normally needs no modification since it comes with stable, reliable settings for printing solid objects with 100 % infill.

The ECO profile supplies settings for objects with loosened infill. This makes objects lighter and reduces the print time and the material consumption. To achieve good results, the settings may have to be adjusted.

We recommend to set the following always for printing ECO objects:

- A hull thickness of 1.0 to 1.5 mm. As a rule of thumb divide the hull thickness by the nozzle tip diameter and set the amount of perimeters equal to the result. Such, a closed, smooth and stable hull is ensured.

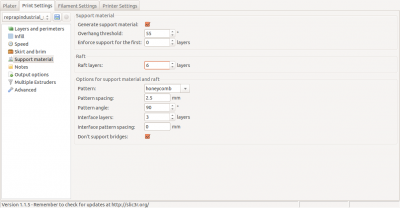

- Honeycomb infill as it provides highest stability at optimal density.

- A minimum infill of 15 %.

- A maximum infill of 30 %. Increasing the infill further does not have a significant advantage compared to a solid body but strongly increases the printing time.

Multiple extruders - Ooze prevention

When using both extruders in one print job (e.g. for bi-colored or multi-material objects) Slic3r provides an “ooze prevention” function that ensures clean start points for every layer.

Since oozing itself cannot be avoided totally, Slic3r generates a “skirt” around the print objects and calculates a “priming position” (normally the starting position).

Whenever a tool change is required, the extruder head moves to this position, reduces the temperature of the extruder not required for the moment by the preset “ΔT” and primes the actual extruder. Then is moves to its next starting point whereby residues of the deselected extruder are shed at the skirt.

The ooze prevention skirt cannot be switched off by zeroing the manually added skirt in the Print Settings “Skirt and brim”.

To ensure an error-free result it is strongly recommended not to deactivate the ooze prevention.

G-code manipulation

The following list contains supported G-code commands that can be used on demand to alter the start and end G-codes in Slic3r or for direct input via the G-code keyboard in the Log menu.

| Command | Effect | Example |

|---|---|---|

G1 | Coordinated Movement X Y Z E | G1 X130 Y85 Z1.75 E4.35 |

G4 S<seconds> | Wait for given duration in seconds | G4 S5 (waits 5 seconds) |

G28 | Home all axes | |

G90 | Use absolute coordinates | |

G91 | Use relative coordinates | |

M80 | Activate build chamber | |

M82 | Set E codes absolute (default) | |

M83 | Set E codes relative while in Absolute Coordinates (G90) mode | |

M104 S<temp> T<extruder> | Set temperature without wait | ex1, ex2 |

M109 S<temp> T<extruder> | Set temperature with wait | |

M140 S<temp> | Set bed target temp without wait | |

M190 S<temp> | Set bed target temp with wait | |

M221 S<extrusion flow multiplier in percent> | Increase/decrease given flow rate |

Deactivating the heating elements after end of print job

Sometimes you may want to start a print job just before finishing time or the weekend. Since there is currently no automatic shutdown function, the 3D printer will then stay on all night respectively some days. With the following description you can alter the End G-code of your print so that the heating elements are shut off after the print job has been finished so that the power consumption is reduced significantly. A side effect is, that due to the fact that the build chamber needs some hours to channel off the heat the cooling process is slowed and thereby internal tensions of the printed object are reduced. To deactivate the heating elements after a print job:

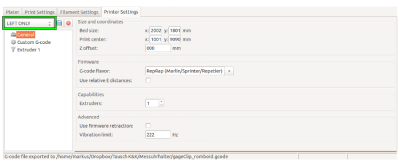

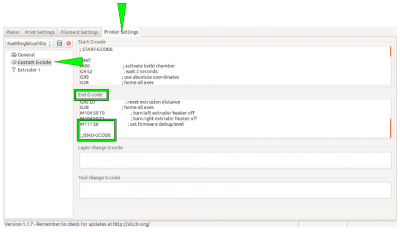

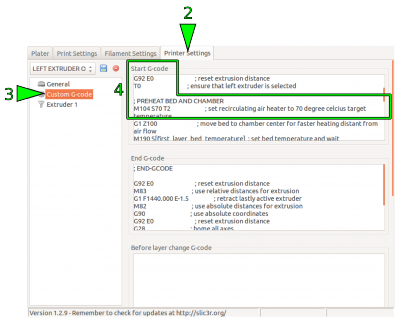

- Open the [Printer Settings] tab in Slic3r and choose the Custom G-code menu.

- Activate the End G-code editor by clicking into the text field.

- Position the cursor in the last line before the

; /END-GCODEentry. - Enter the command

M104 S0 T2

This will set the heating elements of the build chamber to a temperature of 0 °C as the last action of the current G-code.

Adjusting the build chamber temperature

NOTICE

The build chamber temperature is preset to the maximal permissible temperature of +70 °C at delivery.

Exceeding +70 °C will damage interior components of the RepRap Industrial such as stepper motors, bearings and electronics.

Since hitherto the RepRap Industrial is the only commercially available Open Source 3D printer with an actively heated build chamber, common slicing software does not feature ambient temperature settings. For some materials, it is advantageous to modify the chamber temperature together with the other temperature settings. The build chamber's temperature of the RepRap Industrial is set via the “Start G-code” which can be manually altered.

To change the build chamber temperature (in the following example we use our standard Slic3r - other software may differ in denotations):

- Open your slicing software.

- Open the tab “Printer Settings” and choose “Custom G-code”.

Go to the line reading:

M104 S70 T2; set recirculating air heater to 70 degree celcius target temperature

- Change the entry “Sxy” (here S70) by replacing the value xy with the desired temperature, for example 50° C:

M104 S50 T2; set recirculating air heater to 50 degree celcius target temperature

(for logical reasons, the comment should be aligned)

- If you want to keep the settings, save them in the profile (see Slic3r manual).

Any G-code exported with this profile loaded will heat the build chamber to the stated temperature prior to printing.

Operation

In the following you will find more detailed descriptions of functions of the RepRap Industrial. In most cases, these are topics upraised by support requests or in-house lab experiments.

Print bed leveling

The PEI print beds delivered with every RepRap Industrial are custom-made specially to our needs. Due to the manufacturing process, they may show bends and curves which can make handling them a bit tricky. These flaws are accepted due to the superior properties of PEI compared to other subsurfaces when printing ABS. Follow the tips given below and you should have no trouble achieving perfect results.

Of course, the PEI print bed is, like the whole RepRap Industrial, optimized for printing ABS. It also works fine with HIPS, PET-Copolyester, PVA and thermoplastic urethane (TPE-U). Other materials may require a different subsurface, be it another material or a special treatment with tape or glue. Find more information about materials and printing them with a RepRap Industrial in our knowledgebase.

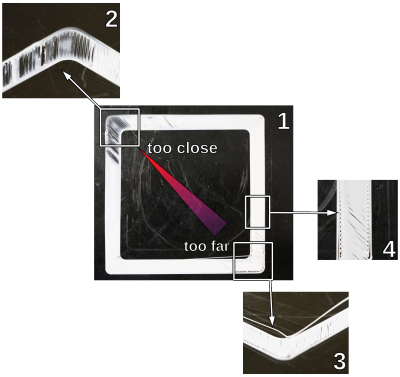

Accurate leveling is vitally important for the print result. Although correct first layer settings can compensate for slight unevennesses of the print bed, false leveling will ruin a print within the first few layers. Evidence for a leveling mistake can be:

- Asymmetrical layer thickness, especially of the first layer, due to lopsided leveling.

- On one side of the print bed the extruded strand is laid on the print bed instead of being spread → the print bed and the nozzle are too far apart.

- On the other side of the print bed the extruded strand is pressed onto the print bed until the nozzle tip is clogged → the print bed and the nozzle are too close.

- Smearing of the extrusion and possibly clogging of the nozzle due to too closely leveled bed.

- Strands do not stick to the print bed but are being pulled away by the nozzle tip. Of course, this can be due to a wrong bed temperature also – better double-check.

- Extrusion of rounded, unjoined strands.

To avoid such irritations, make use of the following tips:

- Always make sure that the build chamber is adequately and uniformly preheated to at least 90 % of the target temperature (e.g. 63 °C for ABS).

The Z-end stop is temperature sensitive and may cause deviating positioning when exposed to temperature variations.

Keep the build chamber doors as shortly open as possible during leveling to avoid too much heat loss. - If you removed the print bed, always re-insert it in the same direction and orientation it had during leveling.

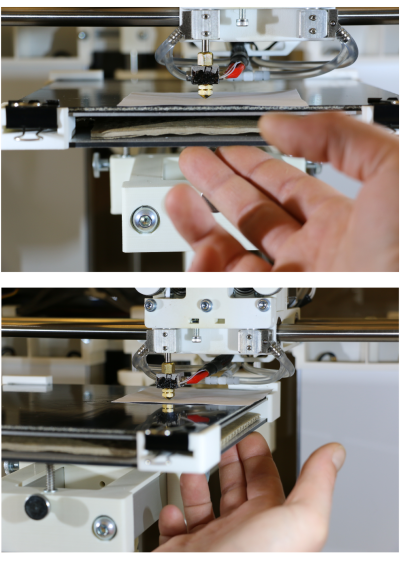

- After adjusting all three leveling points, return the print head to the first position (tap the [Back] button). Check the bed - tip distance by tapping (not pressing) the print bed with a finger next to the nozzle tip: if you see a gap appearing at the slightest touch, the leveling point is correctly adjusted. If even the least pressure is required, the leveling is too high. Repeat this at the other two leveling points. Have a look at the adjacent videos for visual explanation.

- Before waisting time on unsuccessful leveling, please rethink if the currently installed nozzle tip is adequate for the print job. Wider nozzles are more tolerant when it comes to compensating leveling mistakes and may be more suited to the task, especially when printing larger parts.

- If you find it difficult to adjust the three leveling points uniformly with only the spring pressure, place a sheet of paper (not more than standard 80 g/m²) between the nozzle tip and the print bed and carefully push the bed against the tip before fastening the set screws. This way, you ensure a uniform bed - tip distance at all three leveling points.

Calibrating the extrusion

The stability and dimensional accuracy of any printed object require a correct amount of filament conveyed through the nozzle. Too little extrusion and the part will be thin-walled, fragile and likely to break. Too much material is likely to clog the nozzle and ruin the print. The amount of material effectively conveyed through the nozzle is depending on:

- the 3D printer itself - slight variations are possible due to the manufacturing process;

- the actual filament diameter - in the range of the dimensional stability of the filament;

- the printed material's properties - the extruder drive wheel grinds deeper into softer materials, thus reducing the actual diameter;

- the idler tension - high tension will cause the drive wheels teeth to grind deeply into the filament, causing a dilation of the material and a reduced output.

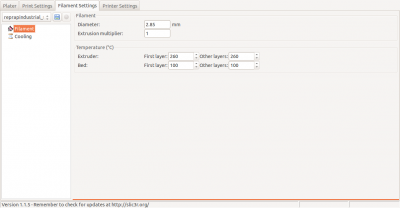

To make sure that the print result is stable and accurate, an extrusion multiplier must be found for every material on every apparatus; it may be that this factor must be found for every spool of filament.

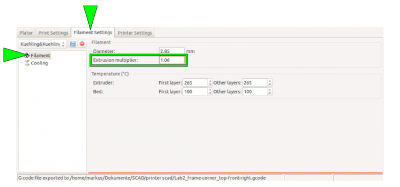

The correct extrusion multiplier is set in the slicing software, compensating for the above named variables.

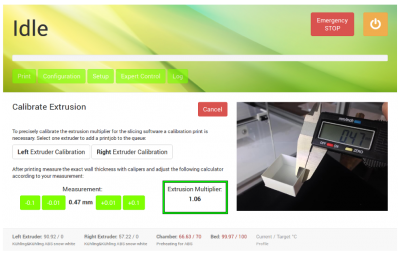

To find the correct multiplier, open the Setup menu at the GUI and choose [Calibrate Extrusion].

A detailed description for ABS filament can be found here.

For other materials, the same procedure applies but you have to prepare a G-code for the test print.

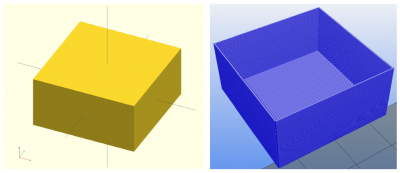

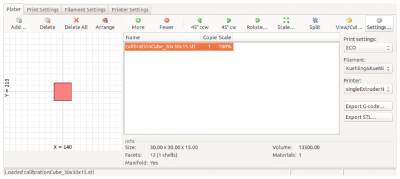

To create a G-code for the extrusion calibration, you need an stl-file of a cube with the dimensions 30x30x15 mm (download here).

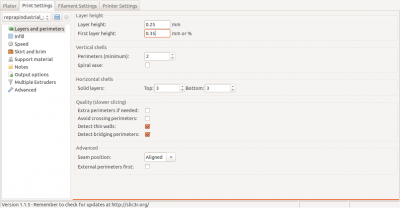

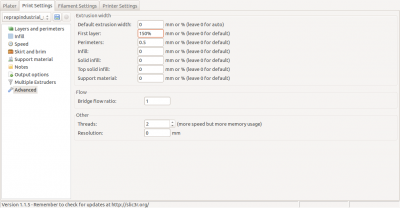

Load the stl-file in Slic3r and select the Print Settings tab.

Choose the SOLID profile as a basis.

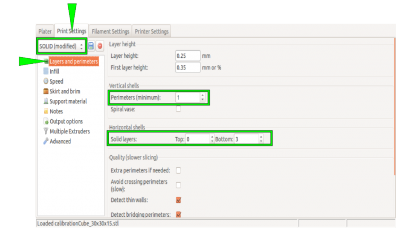

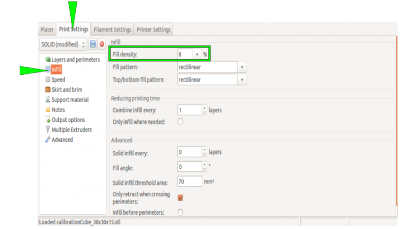

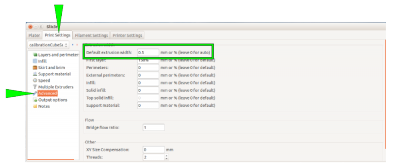

Choose the following settings to make the cube a box without a lid and only one perimeter of 0.5 mm thickness for a wall:

| Layers and Perimeters → Vertical shells Perimeters (minimum) | 1 |

| Layers and Perimeters → Horizontal shells Solid Layers TOP | 0 |

| Layers and Perimeters → Horizontal shells Solid Layers BOTTOM | 3 |

| Infill → Fill density | 0 % |

| Advanced → Default extrusion width | 0.5 |

INFO

Saving these settings for Slic3r as an “extruder calibration” profile will make extruder calibration much more comfortable in the future.

Upload the G-code to your 3D printer, print it, measure the wall thicknesses, and calculate the mean value.

Then open the [Calibrate Extrusion] wizard and enter the mean value.