Table of Contents

Transport and installation

DANGER OF CRUSHING INJURIES!

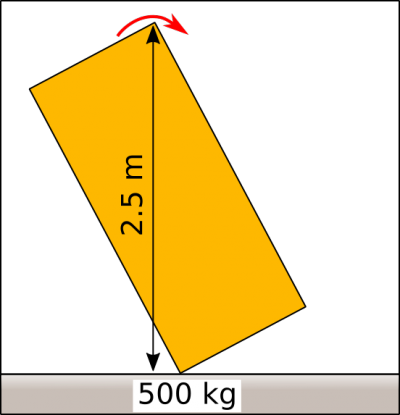

The machine's weight exceeds 250 kg, the centre of gravity is near the middle of the housing in all directions. Toppling of the machine can cause severe crushing damage.

- Always use a pallet stacker or lifting carriage for transport.

- Keep clear of the VP75 during transport and raising.

- If possible, secure the transport box at the eyebolts during raising.

- Avoid sudden movement of the upright machine while lifted on a lifting carriage.

Delivery

The VP75 Additive Manufacturing System arrives at your place fully assembled and can be commissioned directly after setting it up and connecting the power supplies.

Freight box dimensions:

- approx. 226 x 94 x 94 cm (LxWxH)

- shipping weight approx. 400kg

Included in the delivery are:

- the VP75 Additive Manufacturing System

- a pressure reducer for the compressed air supply

- a 2 m power supply cable with Schuko plug and high voltage kettle plug

- a basic tools set

- one spool of sample filament for initial commissioning

The machine is delivered in a wooden transport box. Leave the VP75 packed until moving it to its final installation site for commissioning. Dispose of the packaging in accordance with the local waste disposal regulations.

Further information

Required tools and accessories

| hoisting slings 500 kg (optional) |

| lifting carriage with 1.9 m forks and 300 kg lifting capacity |

| fork lift truck |

| cordless screwdriver with TORX bits (different sizes may be required) |

| open-jaw wrench size 16 |

| open-jaw wrench size 24 |

| RJ45 network cable |

Installation requirements

NOTICE

The machine must not be set up in a surrounding with high formation of dust (e.g. near woodworks etc.). Ingress of particles into the filament supply system can lead to intense cleaning efforts due to clogging of the nozzle and thus immense non-productive time.

Set up the VP75 at a well aerated place with an all-season ambient temperature between 15 and 25°C and a relative humidity of 70%.

Place the VP75 on a flat, carrying and enduring surface with a load capacity of at least 500 kg.

For installation, provide sufficient free space around the machine to make sure you can later remove the transport box and move the machine with a lifting carriage. Kühling&Kühling recommend at least 3.0 x 3.0 m of free space around the machine. To raise the packed machine a ceiling height of at least 2.5 m is required.

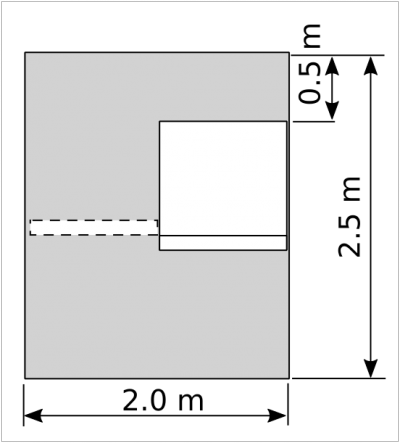

For operation, the required space around the VP75 must at least be 2.0 x 2.5 m and provide 1.0 m free space to the left side to open the door unhindered. To enable unhindered access to the electronic chamber for service and maintenance work a ceiling height of 3.5 m is recommended.

At least 0.5 m free space must be left at the rear side of the VP75 for the power and compressed air supply.

A 230 V power source must be within the range of the connection cable.

A compressed air supply (DN 7.2) must be within range (note: no connecting hose included in delivery). It must provide 6 bar of oil-free, dryed air. Recommended air quality according to ISO 8573-1:2010 [1:4:2].

Also, access to your LAN is required (note: no ethernet cable included in delivery). Your network must provide DHCP IP address management.

Transport

The VP75 has been designed for stationary application. It cannot be moved without adequate equipment. To avoid severe injuries and property damage observe the following notes when transporting the VP75:

- Do not push or pull the VP75 without ground clearance. The machine feet are not designed for withstanding horizontal loads and may brake or tear off. Severe crushing unjuries may result from tipping over. Always lift the VP75 so that the feet have at least 4 cm ground clearance.

- Avert shock loads.

- The centre of gravity is marked on the transport box and on the housing. Observe the marker when lifting the machine to avoid tipping over.

Transporting with the transport box

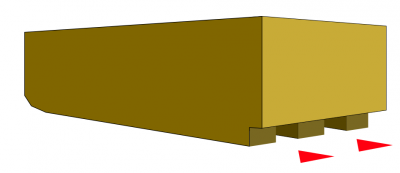

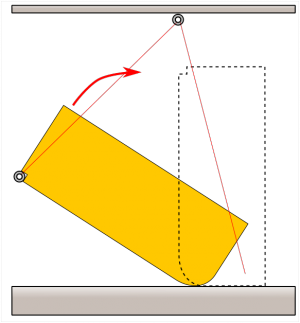

The transport box is designed for transporting the machine lying flat. Fork lift trucks and lifting carriages must provide forks of at least 2 m length for adequately lifting the transport box.

Always position the lifting forks under the box from of of the short sides in the provided gaps.

NOTICE

The eyebolts on the lid of the transport box are not suited for lifting, they are only for securing the box against tipping during setting it upright.

Transport without the transport box

Unpacking and installation

- Use a fork lift truck or lifting carriage to bring the packed machine as near to its setup site as possible.

- To unpack the VP75, first remove the wooden cover marked DOWN. The machine's feet become visible.

ATTENTION Do not screw the feet out yet!

- If there are no eye bolts installed on the top side of the transport box yet, you can find them zip-tied to the machine feet after removing the bottom cover plate. Screw each of them into its metal insert thread at the end of the transport box runners.

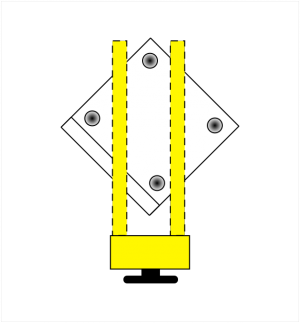

- If present, attach hoisting slings to the eyebolts on the top side of the transport box and secure them at the ceiling. Use the hoisting slings only to secure the machine against toppling. Keep the slings tight until the transprt box stands upright.

- Use the rounded edge to raise the transport box in a vertical position with three people.

- Remove the padding on top of the VP75.

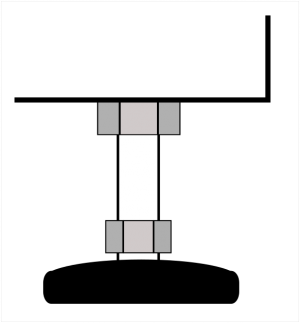

- Manually screw out the feet until all four touch the ground.

- In turn screw out the feet with the size 16 open-jaw wrench by one turn each until the machine is lifted at least 5 mm from the transport box.

- Secure the feet by tightly fastening the counter nuts with the size 24 open-jaw wrench.

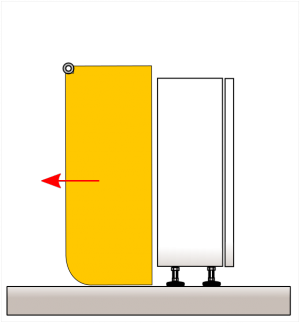

- Carefully pull the transport box away from the VP75.

The full scope of delivery, including any parts ordered additionally, is listed in detail on the delivery note.

After unpacking, inspect the VP75 for:

- damage in transit

- completeness of the delivery

If you notice any deviants, please inform the hauler and the manufacturer immediately.

Do not put the VP75 to use with defective parts.

Failure to inform Kühling&Kühling in time will render any rectification claims void. The respective terms and deadlines are stated in the sales contract.

INFO

Kühling&Kühling strongly recommend to store the transport box for later use. Find detailed information about repacking the machine for shipping in the Service Guide.

- Use a lifting carriage to move the VP75 to its final position.

After setting the machine up it must be connected to the power supply, the compressed air supply and the data network. All required connections are at the rear side of the VP75.

- Make sure that the main switch is set to <0>.

- Unpack the supply cable and connect it to the mains plug.

- Connect the Schuko plug to a 230 V socket.

- Connect the compressed air supply to the pressure reducer.

- Connect the VP75 to your data network via the RJ45 ethernet plug.

Initial commissioning

After set-up has been completed the further commissioning of the VP75 is done via the web-interface and the touchscreen as described in Initial Commissioning.

Decommissioning

Decommissioning may be necessary on two occasions: the temporary decommissioning if the machine is to be out of operation for a limited time (e.g. moving) or the permanent decommissioning if the machine has expired its lifetime and shall be disposed.

Temporary decommissioning

If you need to take the VP75 out of operation to move or store it, regard the following information:

- Remove remaining filament from the supply system.

- Clean the VP75, especially the extruder nozzles.

- Move the WHDDNM? into the home positions.

- Disconnect the mains cable and the network cable. Store them together with the VP75 (e.g. fixed with adhesive tape inside the build chamber).

- Protect the build plate surface and the touchscreen against scratching.

- Secure the extruder head and the build chamber door with strapping tape against moving (see Transport).

- Cover the VP75 with a plastic tarpaulin.

NOTICE

Do not cover the VP75 with a textile sheet since the fibers may enter the supply system and clog the nozzle after recommissioning. Use lint-free plastic sheets only.

Storage

If the VP75 must be stored away, choose a leveled storage site and make sure that the machine does not stand on a ledge.

Before storing it, clean the VP75 and protect it from dust with a plastic tarpaulin or air cushion foil.

NOTICE

Do not cover the machine with a textile sheet since the fibers may enter the supply system and clog the nozzles after recommissioning. Use lint-free plastic sheets only.

The storage ambient conditions for the VP75 and its components are stated in the data sheet. For recommissioning after lengthy periods of storage follow the information given in initial commissioning.

Permanent decommissioning

If you want to dispose of the VP75 or if it is damaged beyond repair:

- Take the VP75 out of operation as described above.

- Disassemble all components according to their recyclablility and dispose of them adequately and lawfully.

INFO

Components may bear valuable elements such as rare earths, or may be reusable. Do not waste them by inadequate and thoughtless disposal.

Environment, recycling and disposal

When used as intended, the VP75 presents no environmental danger.

The materials used for printing can be environmentaly dangerous when handled improperly. Always observe the manufacturer's safety data sheet and process plastics only within the limit values specified therein and with respect to the safety instructions.

Generally, consider the environment: the auxiliary and operating materials of the VP75 can be dangerous to environment and health.

Awareness and foresighted behavior help avoiding ecological and personnel damage.

Components may bear valuable elements such as rare earths, or may be reusable. Do not waste them by inadequate and thoughtless disposal.

Environmentally hazardous substances must not trickle into the soil or enter the sanitation. They must be stored in suitable containers and be disposed off adequately and in accordance with local and national regulations.

The VP75 is recyclable due to its low-pollution equipment. Nonetheless, the European Guideline 2002/96/EG (Waste Electrical and Electronic Equipment - WEEE) and the German Elektro- und Elektronikgesetz (ElektroG) forbid the disposal of the apparatus via household garbage. For environmental friendly recycling and disposal of the VP75 please contact a certified electronic waste management professional.

INFO

Kühling&Kühling emphasize that there is no redemption obligation in this regard.