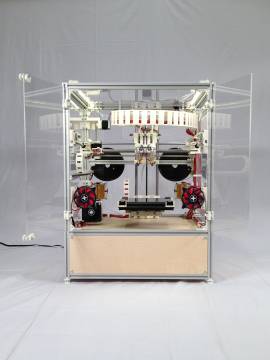

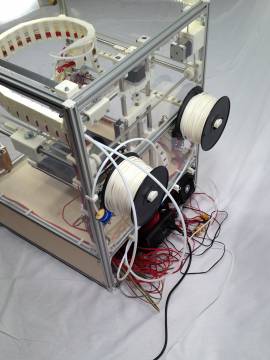

Kühling&Kühling RepRap Industrial 3D Printer (Prototype)

At the beginning of 2013 Kühling&Kühling demonstrated a pre-production prototype of the RepRap Industrial at FabCon.3D tradeshow in Erfurt/Germany and started to accept pre-orders on the final series production model.

This revision was not actually manufactured, so these pages are for historical reference only.

Kühling&Kühling RepRap Industrial

| Durable ABS prints without warping. Heated build chamber. Dual extruder printhead. Super easy maintenance workflow. |

This is our RepRap-based desktop 3D printer that can reliably print objects from ABS plastic without warping – a problem well known from many desktop-grade 3D printers and RepRap designs.

The “Kühling&Kühling RepRap Industrial” has a fully enclosed frame with powerful recirculating chamber heaters that raise the ambient air temperature up to 70°C. With minimized thermal stress the printed objects adhere flat to the build platform and allow for dimensionally accurate results.

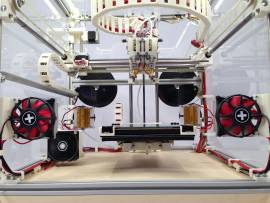

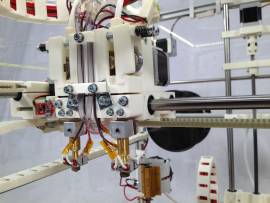

Featuring two extruders this 3D printer can print with different nozzle diameters – printing the visible outer shell of an object in fine details while saving production time on the infill structure by using a bigger extrusion nozzle. Or you can do pretty two-color prints from equal tips.

The whole machine was developed for productivity, so you can expect minimal maintenance time for several recurring tasks like swapping filament, changing nozzle tips or levelling the build base. All sub-assemblies are easily accessible so you get the job done quickly.

Specifications

- Filament diameter: 3 mm

- Build volume: 200 mm x 200 mm x 200 mm

- Number of extruders: 2

- Overall dimensions: 800 mm x 600 mm x 600 mm

Features

- Specifically aimed at printing ABS with zero warping, low maintenance effort through highly accessible sub assemblies

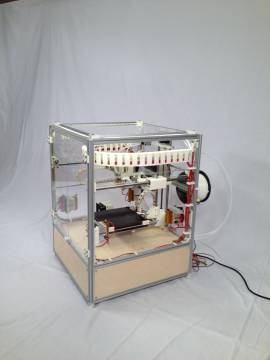

- Rigid frame made of t-slot aluminium extrusion

- Fully enclosed by acrylic and wood, doors on the front

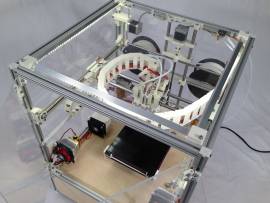

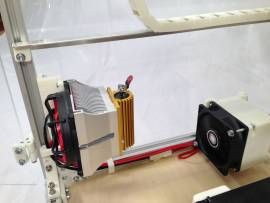

- A heated chamber capable of 65-70 °C recirculating air temperature

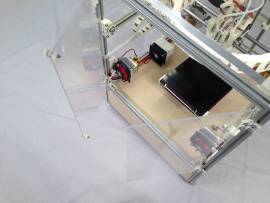

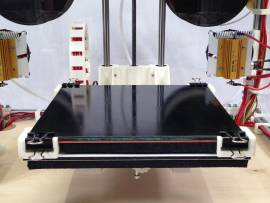

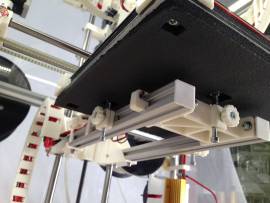

- Heated PCB print bed

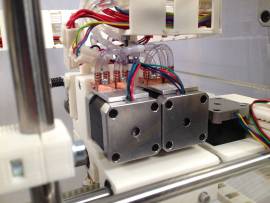

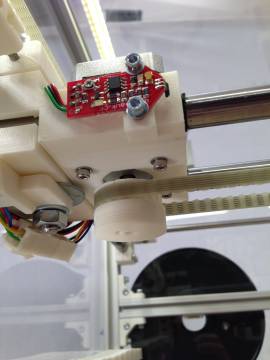

- Water cooled hot-ends and extruder steppers to ensure reliable extrusion in high ambient air temperature

- Fully parametric Open Source design

- Dual extruders, primarily for use with different nozzle diameters for perimeters/infill to save printing time on big objects

- Activated-carbon air filter to remove unpleasant smell of molten plastic

- Semi-automatic print bed levelling makes calibrating the machine a matter of seconds

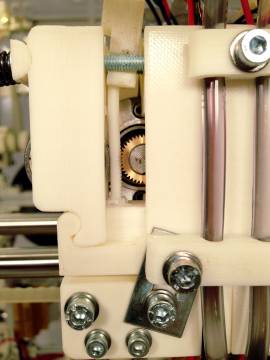

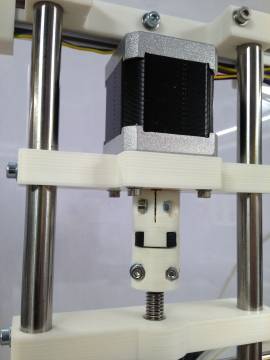

- Z-leadscrew bearing supported on both ends, sugru spider coupling for absolutely wobble-free operation

- 12 mm precision ground shafts with LM12UU linear ball bearings on all axes (will be replaced by Igus RJMP, see below)

- Tool-free belt tensioning with built-in thumbwheels

- Direct-drive extruders with high torque geared stepper motors

- Permanent printbed material (polyetherimide (PEI) glass fabric composite) – no Kapton or PET tape needed

- Adjustable nozzle height to align both extruders on the same level

- Custom designed, precision extruder drive gears to provide enough grip on the filament in a heated enviroment

- Integrated LED lighting

- All-metal hot ends from reprap-fab.org with 40 W each for short heat up time

- Raspberry Pi with a 10″ capacitive touch display for ethernet enabled standalone operation

- Touch optimized user interface for the raspberry pi is in development

- Magnetic door locks

Upcoming development

- 400 mm x 400 mm x 400 mm super-sized printer based on our extremely parametric design

Open Source

The development version of our OpenSCAD source files are available on GitHub at https://github.com/kuehlingkuehling/RepRap-Industrial-200. A Bill of Material as well as build instructions and details on electronics and wiring will be published as we lock down v1.0 and sales start.