Table of Contents

Service guide for RepRap Industrial

The instructions below are meant to enable you to perform troubleshooting, repair and cleaning tasks adequately and without damaging the machine.

Read the respective guide carefully before you start to work on the RepRap Industrial 3D printer.

In some cases you may need to lookup additional information for a specific task. Since we are trying to provide all necessary information independent from the hard- and software version of your actual RepRap Industrial you may have too choose from different sources.

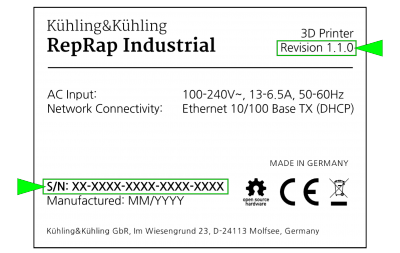

To find the valid hardware revision of your 3D printer, check here.

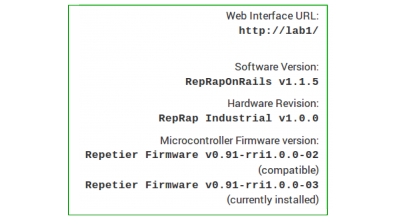

To find the valid software version of your 3D printer, check here.

In case you are unsure about steps mentioned in this guide just ask for help any time - we will as always do our best to answer all questions that may arise.

Support requests - required information

In case you require support and contact us please always provide the following information:

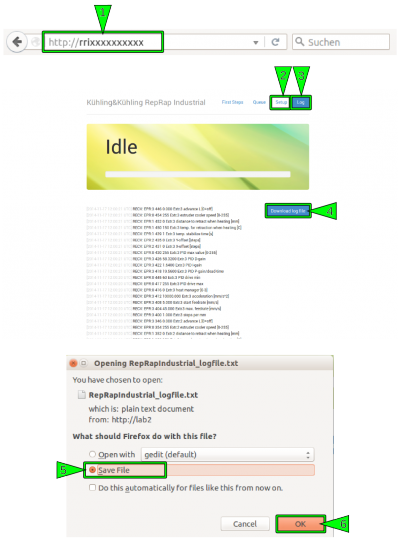

- The .log-file, downloaded via the web interface's Setup tab.

INFO

When downloading the .log-file via the web-interface, please open the Setup tab first so that the currently set EEPROM data are written into the log.

The log file saves all operating and communication commands since the initial commissioning and exports the last 10,000 commands into a data file. Due to this, it may require a few minutes for the system to gather all necessary data before the download menu appears.

- All system information provided on the Setup menu

(not valid for RepRapOnRails v1.0.5 or older).

Additionally, the following information may be helpful for examining and evaluating your specific request:

- Photos of unsuccessful prints often give a clue of what may have gone wrong.

- G-codes of above mentioned prints and the respective .stl-data allow for reprinting and reproducing your print job and help identifying faults.

- Photos and short videos of components, be they damaged or behaving oddly, always provide some clarification.

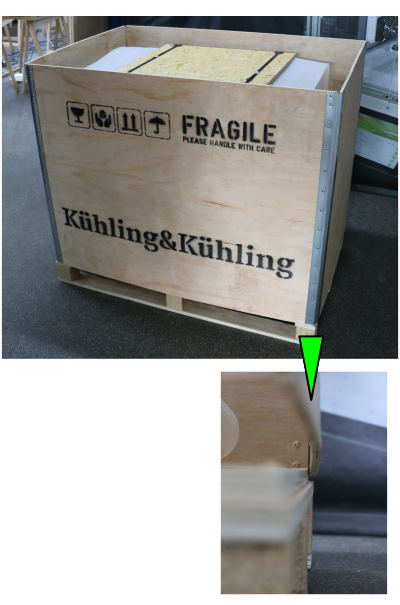

Packing and transport safeguarding

If the RepRap Industrial is to be shipped (e.g. for a full manufacturer's in-house inspection), it must be thoroughly packed and all moving components must be carefully secured against shifting to avoid transportation damages.

INFO

Replacement of parts damaged due to improper transport securing will be carried out at your costs.

Safeguarding of movable components

You will need the following material:

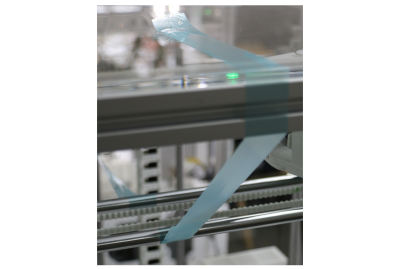

- removable strapping tape

(e.g. tesa® Strapping 64250, Scotch® Strapping Tape 8898 Blue) - packing foam foil

(any PE-foam for common packing applications) - cardboard

The following description assumes that:

- all axes are in their respective home position;

- filament has been unloaded and the 3D printer has at least been briefly cleaned;

- the 3D printer has been switched off, disconnected from the power supply and cooled down;

- all cables have been removed from the rear side.

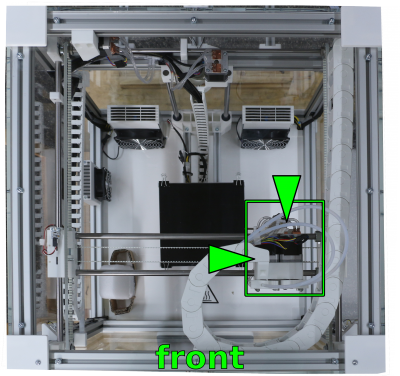

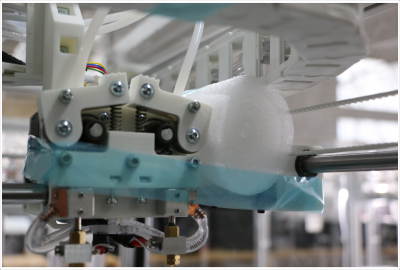

The first and most important component to be secured is the extruder head. It is mandatory to fix it exactly as shown here. Otherwise sensors and other components may be damaged beyond repair and must be replaced.

- Move the H-bridge to the front and the extruder head to the right-hand side.

- Place a foam coil between the extruder head and the right X-axis shaft carriage and push the extruder head against the coil.

- Fasten the extruder head together with the carriage by entwining them with strapping tape.

Make sure to tension the tape so that any extruder head movement is prevented.

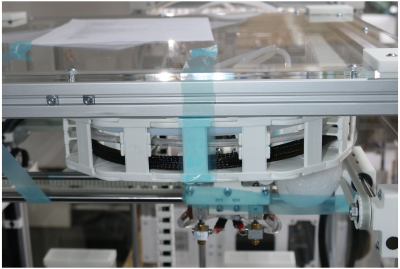

- Fasten the energy chain to the printer top cover.

- Fix the H-bridge with strapping tape against forward movement by fastening it to one of the Z-Axes.

- Fix the H-bridge with strapping tape against backward movement by fastening it to the printer top cover.

Make sure to tension the tape to prevent forward/backward movement of the H-bridge.

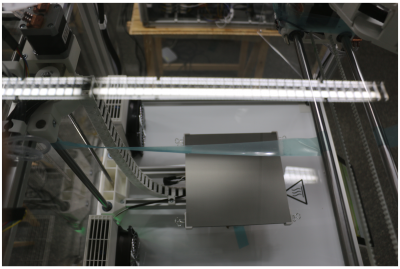

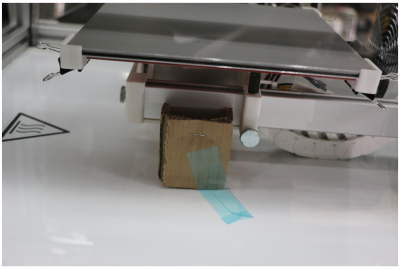

- Cut and prepare a cardboard support as depicted.

- Place the support underneath the print table and fix it with strapping tape.

Packing for transport

After safeguarding, the 3D printer is ready for packing. You will need the following material:

- 4x lashing strap or tension belt

- closed surface transport pallet

- packing foam foil

- 4x anti-slip mats 50 x 50 mm (only 3D printers without rubber feet)

- OSB transport top cover (or similar) 700 x 700 x 25 mm

- delivery transport box side cover frame

- delivery transport box lid

The description refers to using the original transport box the 3D printer was delivered in. If you disposed of the box, make sure to provide adequate replacement.

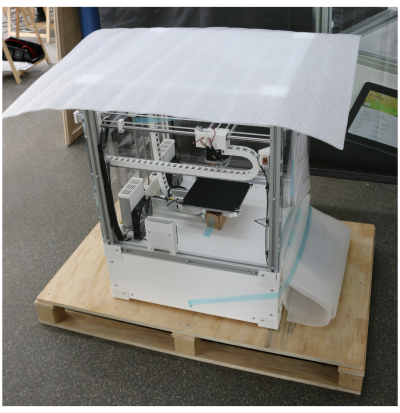

- Lift the 3D printer onto the center of the pallet.

- Place a suitable piece of transport foam foil on top of the 3D printer.

- Place the cover plate on top of the 3D printer.

- Fasten the 3D printer with two lashing straps to the pallet.

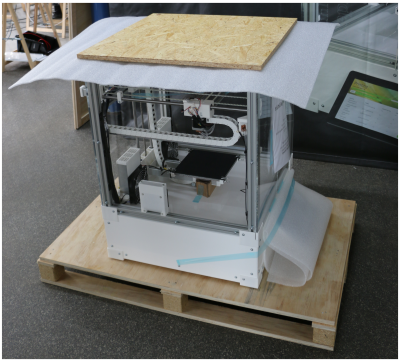

- Lift the side cover frame onto the pallet.

Make sure that the grove of the pallet fits smoothly.

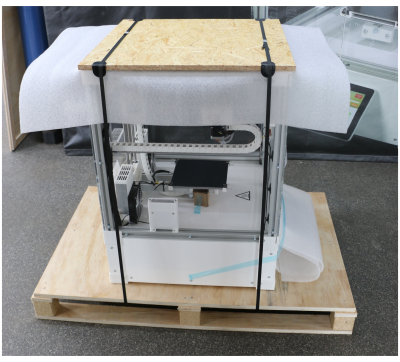

- Close the box with the lid.

Make sure that the lid smoothly fits into the side cover frame.

- Secure the transport box with two lashing straps on the pallet.

- Attach all necessary labeling on the outside:

- dispatch note

- UP sticker (present on the original transport box)

- FRAGILE sticker (present on the original transport box)

- PROTECT FROM WEATHER EFFECTS (if required, present on the original transport box)

Hardware components and manual tasks

Maintenance intervals

Daily (end of shift)

| Where | What | Tools / To Do |

|---|---|---|

| Build chamber | - remove filament residues | brush, hand broom, vacuum cleaner |

Monthly (150 operating hours)

| Where | What | Tools / To Do |

|---|---|---|

| Timing belt | - check the tension; re-tension if required | Description |

| Shafts | - check for dryness; lubricate if required | Description |

| Cooling circuit | - check hoses for excessive bubbles; refill if required - check hose connectors at the LEDs and the stepper drives for correct positioning; refasten if required | Description |

| Dust wiping sponge | - check for cleanliness; clean or replace if required | rinse with fresh water and dry thoroughly |

Semiannually (1.250 operating hours)

| Where | What | Tools / To Do |

|---|---|---|

| Air filter | - exchange filling | Description |

Yearly (2.500 operating hours)

| Where | What | Tools / To Do |

|---|---|---|

| Z-axis spindle drive | - check for fast seat: with the 3D Printer switched on, grab the print table near the elevator and try to lift it → play of the table on the spindle requires replacement of the spindle nut → if you can lift the entire assembly including the spindle, the adjusting rings must be refastened | Description |

Cleaning recommendation

DANGER OF INJURY

Some plastics need very aggressive solvents that may cause intoxication, caustic burns, skin, eye and/or mucosal irritations, allergic reactions and other medical consequences. Solvents may emit flammable or toxic vapors or be corrosive.

To avoid injuries and accidents due to use of solvents:

- Always observe the safety information provided in the manufacturer's safety data sheet concerning possible dangers, handling and adequate storage.

- Always wear adequate protective equipment.

- Do not use solvents in a surrounding not suited to the task. If required, adequate aeration or exhaust ventilation has to be provided.

- Always use adequate containers for handling and storing solvents.

- It is the owner's responsibility to provide any necessary equipment and protective gear for every person operating the RepRap Industrial 3D printer.

DANGER OF BURNING

The build chamber interior may reach temperatures of up to 70 °C (158 F°), the print bed may reach temperatures up to 130 °C (266 °F) and the hot ends may reach temperatures up to 300 °C (572 °F). Touching components can cause burning injuries ranging from burn blisters to medium aching burns. Before cleaning any component inside the build chamber:

- Move the print head to the maintenance position (GUI → [Expert Control] → [Print Head Maintenance Position]).

- Switch preheating of the 3D printer off (GUI → [Print] → [Preheat Chamber/Bed OFF]).

- Let the printer cool down to at least 52 °C.

NOTICE

Acetone is the most effective solvent for ABS and thus recommended for most cleaning purposes at the RepRap Industrial 3D printer.

To remove residues of other plastics than ABS, refer to the knowledge base or the respective manufacturer's data sheet for suitable solvents.

Regard the following when using solvents for cleaning purposes:

- Do not use solvents inside the build chamber. They may evaporate and produce fumes that can dissolve plastic components (e.g. the energy chain links) and printed objects. Always remove components from the build chamber before treating them with a solvent and dry thoroughly before re-insertion.

- Do not use liquids inside the build chamber. These may enter the electronic chamber and cause short circuits or otherwise damage electronic components.

Housing

Although during normal operation it is not necessary to clean the 3D printer daily, regularly dusting reduces the probability of dust entering the feed system and causing clogging. Also, the visual appearance of the 3D printer is improved and damaged components are more easily detected.

All components of the RepRap Industrials' housing can be cleaned with mild household detergents (e.g. dish soap, glass cleaner) and lint-free towels.

Do not use abrasive detergents or scouring pads as these will scratch and blind the acrylic glass covers and the touchscreen surface.

Material residues should be removed routinely from the build chamber. Use a soft brush or a low-running vacuum cleaner to remove loose material shreds.

Touchscreen

If required, use a microfiber or spectacle cloth moistened with glass cleaner to wipe the touchscreen.

Print bed

PEI is highly resistant to a lot of solvents. It is particular compatible with acetone and isopropyl alcohol.

If you experience insufficient adhesion of objects to the surface during prints, it is advisable to thoroughly clean the print bed with an acetone-soaked lint-free cloth.

Grease residues on the surface of the print bed (i.e. fingerprints) can lead to poor adhesion. To degrease, apply isopropylalcohol to a lint-free cloth and thoroughly wipe the surface. During further use, regular removal of grease residues with isopropyl alcohol will prevent poor adhesion.

Use acetone as solvent to remove ABS residues from the print bed. Apply the acetone to a cloth and wipe the print bed rather than dousing it directly.

Other material's residues are best removed with a lint-free towel soaked in a suitable, non-corrosive, non-toxic solvent. Observe the manufacturer's safety data sheet when handling plastic solvents. Make sure to thoroughly wash off any residues. Remaining smear may lead to increased adhesion, which can render it impossible to release printed objects without damage.

Hot ends

Cleaning the hot end nozzle tip is required quite often compared to other components of the 3D printer. Dust ingression through the filament supply system, coking of material, and storage in a dusty place may lead to clogging of the tip's bore.

An imprecisely (too closely) leveled print bed, too low extrusion temperatures or too high an extrusion speed can lead to the nozzle tip choking itself.

In any of these cases, a decreasing print quality and slipping of the drive gear will be the first visible effects. Removing and cleaning the nozzle tip is then necessary; the description below should remedy the problem, as long as no hardware defect is present.

Cleaning the extruder hot end barrel is only required if it is clogged with coked material or foreign particles. It is recommended after dissembling the hot end at material change (installing a different material).

INFO

In areas with high dust formation, especially from textile fibers and similarly flexible particles, the risk of the nozzle tips to become clogged is highly increased.

Filament drive gear

Slipping of the drive gear is almost always the first and visible consequence of a clogged nozzle.

Other conditions (e.g. too high idler tension) may also cause the drive gear to grind into the filament and fill with abrasion. Material transport will stop and the print job will not be finished.

Regard that the printer will nevertheless continue to print if not aborted by the operator.

Clean according to the description below.

Remedying clogging

Required tools

- dental pick hook or needle

- material specific solvent

- pipe cleaner

Additional information

Procedure

To clean a nozzle tip:

- Screw off the nozzle tip.

- Roughly remove material residues mechanically (e.g. using a brass wire brush - wear protective goggles!).

- Drop the nozzle tip into a suitable solvent and wait for the residues to be loosened or completely dissolved.

- Remove remaining material mechanically.

- Dry the nozzle tip thoroughly before re-installation.

To clean the inner bore of the extruder barrel:

- Dissemble the hot end as described.

- Run a pipe cleaner through the barrel's bore to remove loose particles.

- Dissolve any residues in a suitable solvent.

- Remove remaining material mechanically.

- Dry the barrel thoroughly before re-installation.

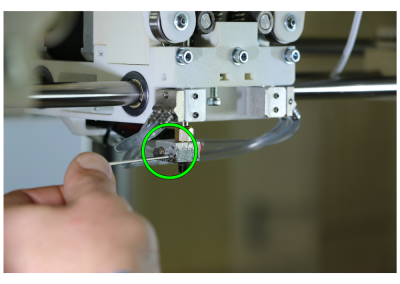

To remove particles and abrasion from the feed system:

- Remove the filament strand from the supply system.

- Take out the dust wiping sponge from the filament inlet, rinse it with water, and dry it thoroughly.

- Scrape the teeth of the drive gears with a pointed tool (e.g. dental pick).

- Reinstall the supply hoses and the dust wiping sponge.

Completion

After having re-installed or exchanged all components, reload the filament and run the [Prime Extruders], and the [Print bed leveling] wizard.

Shaft lubrication

NOTICE

The following only applies to hardware revisions up to 1.1.0.

Later hardware revisions are equipped with new slide bearings and do not need any lubrication.

All slide bearings of the RepRap Industrial are equipped with dry-run linear slide bearings. Nonetheless, the permanent temperature variation inside the build chamber may lead to stick-and-slip effects on the bearings, especially at the Z-axis. Lubricating the shafts may then be necessary.

Required tools

- Ballistol Universal (manufacturer's website (DE))

- paper towel or lint-free cloth

NOTICE

Do not use any other lubricant. The dry-run slide bearings are sensitive to oils and fats and may get irreparably damaged when greased falsely.

Applying lubricant

If you notice strong vibrations of the print table during homing and leveling or if your printed objects show increasingly rough vertical irregularities:

- Apply Ballistol Universal to a paper towel.

- Coat the shafts with a thin layer of the lubricant.

- Wipe off excessive lubricant.

INFO

During preheating, the freshly applied Ballistol Universal will emit a smell that you might find offending.

This is not harmful and will wear off in a couple of hours.

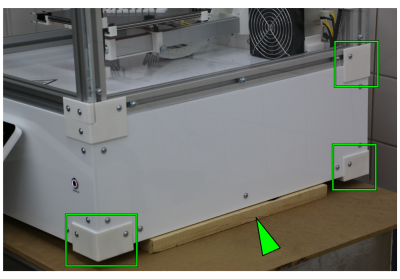

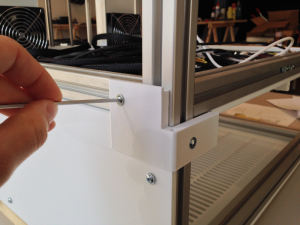

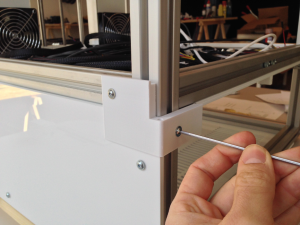

Opening the electronic chamber

To access the cooling system or the control elements, you have to remove the left or the right side cover panel. The description below applies to either side.

ELECTRIC SHOCK HAZARD!

Electric shock can cause severe injuries. Never open the electronic chamber when the 3D printer is powered on.

Always shut down and power off the 3D printer and disconnect the power supply before removing covers and working on electronic components. Allow the power supply to discharge for at least one minute.

NOTICE

Electrostatic discharge can damage electronic components. Ground yourself before touching electronics.

Required tools

- Allen wrench #2.5

Additional information

Removing

Shut down the printer via the touchscreen panel, switch off the main power switch and unplug the supply cable. Open the electronic chamber of the 3D printer in the following sequence:

- Slightly tilt the apparatus to the opposing side and place a square length of wood underneath the bottom.

DANGER OF CRUSHING!

Capsizing of the 3D printer can cause crushing injuries and damage the housing beyond repair. Make sure the apparatus does not topple.

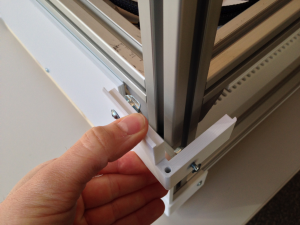

- Loosen (do not remove) the hexagon socket screws of the feet and the upper hind cover angle.

- Turn the hammerhead nuts by 90°.

- Remove the feet and the angle.

- Loosen (do not remove) the hexagon socket screws of the cover panel.

- Turn the hammerhead nuts by 90°.

- Remove the cover panel.

- Loosen all screws around the white acrylic side panel and take the panel off. You now have access to the electronics driving the RepRap Industrial.

Reinstall in reverse order, remove the wood and restart.

Changing the nozzle tip

Printing with another nozzle diameter, cleaning or change of material all requires unscrewing and remounting the nozzle tip. Although not a complicated procedure, make sure to read the following description thoroughly to avoid damaging the hot-end.

BURNING HAZARD!

Before unscrewing a nozzle, the filament must be removed from the hot-end which may require heating to extrusion temperature. Depending on the installed material temperatures up to 300 °C may be necessary that can cause severe burns.

- Be careful not to touch hot components.

- After loosening the nozzle let the extruder cool down before starting to work on it.

Required tools

- Allen wrench #1.5

- 2x open-jaw wrench size 8

Additional information

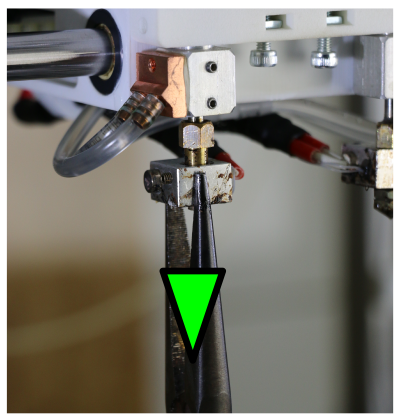

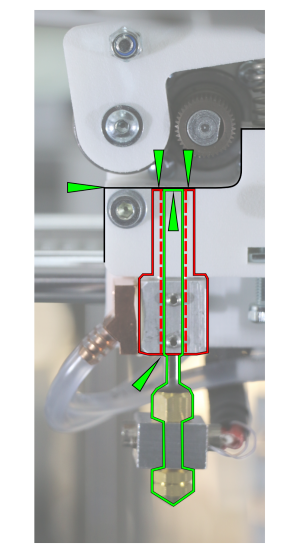

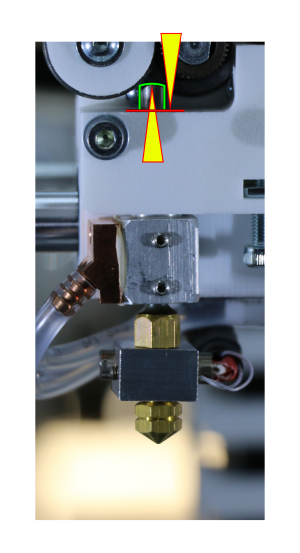

Removing the nozzle tip

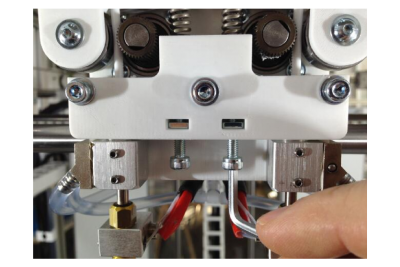

After the extruder has cooled down:

- Open the Expert Control menu, tap the [Printhead Maintenance Position] button and wait until the print head has moved to the middle front position.

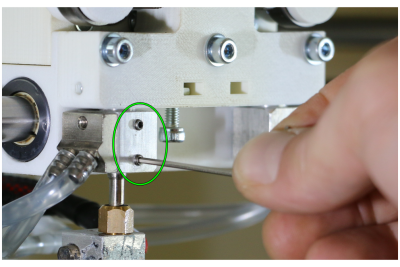

- Loosen the two set screws at the hot end mount with a #1.5 Allen wrench.

NOTICE

Do not loosen the nozzle tip without loosening the barrel set screws and countering the melter. Distorting the barrel may damage the glued connection.

If solidified material hinders loosening the nozzle tip effortlessly, heat up the extruder to the specific extrusion temperature and loosen the tip 2 or 3 turns. Do not unscrew the heated tip totally. Dropping the hot nozzle tip will damage the acrylic bottom.

Afterwards, turn the extruder off and wait until it has cooled down before completely removing the nozzle.

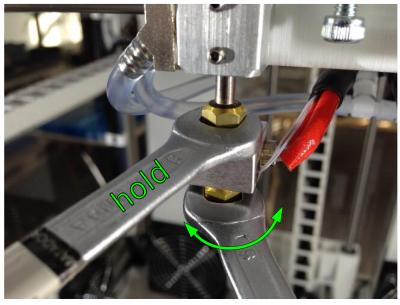

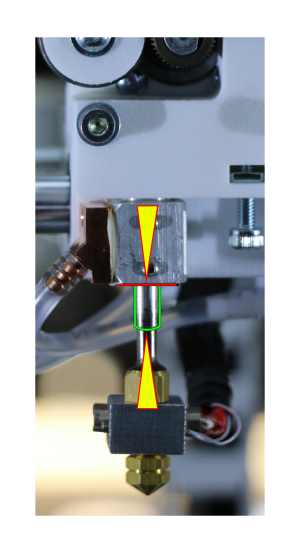

- Loosen and remove the nozzle tip with a size 8 wrench while countering with another size 8 wrench at the hex section of the melter.

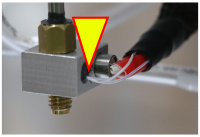

Installing a new nozzle tip

- Screw the nozzle tip onto the melter thread.

NOTICE

Overtightening the nozzle tip may shear off the thread. Distorting the barrel may damage the glued connection of the barrel and the melter.

Do not fasten the nozzle tip without countering.

- Carefully fasten the nozzle tip with a size 8 wrench while countering with another size 8 wrench at the melter.

- Run the Print Bed Leveling wizard.

INFO

Prior to installation clean the nozzle tip with acetone or isopropyl alcohol to remove any dust, oil, shavings, etc., and dry it thoroughly.

Clean removed nozzle tips adequately and store them in a dry, dust-free box.

Changing the hot-end barrels

For cleaning purposes, when changing the print material or in some problem cases you have to remove and replace a hot-end barrel.

Required tools

- Allen wrench #1.5

- tongs (optional)

Additional information

- Software manual: filament change

- Troubleshooting: P1

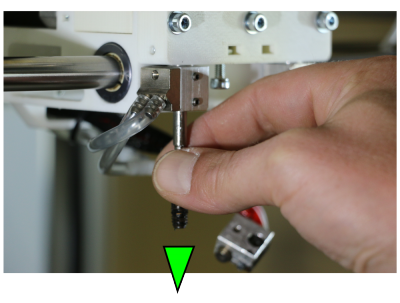

Deinstalling the barrel

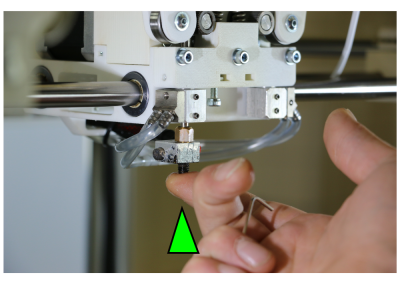

- Remove the nozzle tip as described above.

- With both set screws loosened, carefully push the barrel to the limit up the nozzle seat.

- Fixate the barrel by fastening one of the set screws.

- Loosen the set screw of the heating block with a #1.5 Allen wrench.

- Carefully pull the heating block off the barrel and let it dangle at its cables.

Installing a new barrel

Install the left extruder nozzle first:

- Carefully push the barrel to the limit up the nozzle seat and fixate it by fastening one set screw.

- Slip the heating block onto the melter up to the hex section and fasten the set screw tightly.

INFO

A sheer metal surface of the heating block's bore and soundly fastening the set screw are vitally important for the heat transfer from heating block to melter.

Prior to installation check the inner surface of the bore. If required, refasten the set screw after shortly heating the hot-end to extrusion temperature to soften plastic seeped into the thread.

NOTICE

Take care not to damage the thermistor cable.

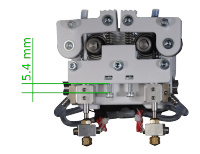

- Loosen the set screw and lower the barrel until its upper end is level with the hot-end mount's upper rim.

- Fasten the two set screws with a #1.5 Allen wrench.

- Install the right extruder nozzle in the given order but a little above the left hot-end.

- Run the Print Bed Leveling wizard.

- Run the Calibrate Extruder Offset wizard.

Replacing the heating block

The thermistor cables of the heating block are very fragile and vulnerable to bending and twisting.

A defective thermistor cable will set the 3D printer into Dry run mode which means no further printing is possible until fault remedy.

If a thermistor cable is broken, the complete heating block assembly must be replaced.

Required tools / parts

- pre-assembled heating block replacement part (order via sales@kuehlingkuehling.de).

- Allen wrench #1.5

Additional information

Heating block exchange procedure

To deinstall the heating block:

- Move the print head to the maintenance position.

- Shut down the 3D printer, disconnect it from the power supply and let it cool down.

- Remove the nozzle tip and deinstall the heating block as described previously.

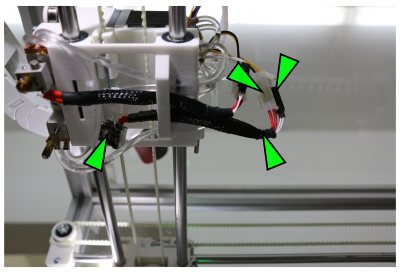

- Follow the cables of the heating block at the rear of the extruder head. Disconnect both cable connections.

Make sure not to damage the female plugs.

- Pull forward the heating block out of the extruder head.

NOTICE

Take care not to damage the thermistor cables.

- Install a new heating block in reverse order.

The cable connectors are protected against polarity reverse so that mismatching is impossible.

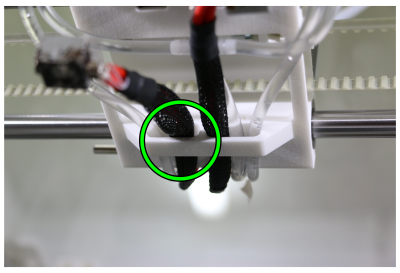

Make sure to adequately position the cable harness so that it cannot hang loosely. The cable harness must be fed through the provided lead-through.

Cooling water pump

Required tools

- Coolant Innovatek Protect IP ready-to-use ¹ (max. 250 ml)

- Allen wrench #2.5

¹ Order directly via sales@kuehlingkuehling.de, the manufacturer's webshop (http://innovatek.de, manufacturer part number: 500473) or related distributors.

Demounting and refilling

If you need to access the cooling water pump (e.g. for refilling coolant), you first have to remove the right-hand side cover of the electronic chamber. Then:

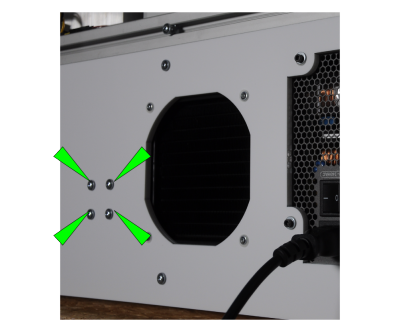

- Unscrew the four holding screws on the left side of the cooling unit radiator grill at the rear cover.

- Pull the pump out of the chamber. The hoses' lengths are designed for this.

- Remove the pump's lid by turning it counterclockwise and pulling it off.

- Refill with coolant up to the level indication.

- Let the pump run for some minutes. Monitor the coolant hoses and check that air bubbles run freely. If necessary, carefully flick the hoses to free trapped air. When all air bubbles have left the cooling system, check the filling level of the pump again and refill to the upper limit.

- Press the lid into the housing and turn it clockwise. Make sure the lid is positioned fast in its seat and locked.

- Reinstall the pump at the rear cover and close the electronic chamber.

Air filter

Required tools

- Allen wrench #3

- activated charcoal granules (∅4 mm, 10 g)

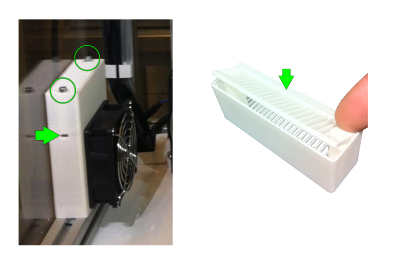

Refilling the charcoal container

Exchange the activated charcoal of the air filter every six month:

- Switch the 3D printer off and let it cool down.

- Unscrew the two screws of the container with a cross-tip screwdriver and take it of.

- Open the lid of the container (press down at one side) and dispose of the used up granules.

- Refill with fresh charcoal granules.

- Close and reinstall the container. Make sure that the square nuts are in place when fastening the screws.

Extruder idler lever

Required tools

- Allen wrench #3

Adjusting the preload

At delivery, the idler lever preload is preset to work with the standard material Kühlung&Kühling ABS snow-white. To print other plastics it may be necessary to adjust or readjust the tension of the idler lever spring.

Too high tension of the idler lever spring may result in the gear drive to slip and grind into the filament. Too low tension of the idler lever spring may result in slipping of the gear drive. In both cases the print will abort due to insufficient material transport.

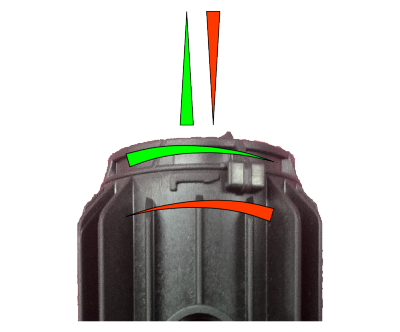

Adjust the idler lever spring pressure by turning the tensioning screw with a metric #3 Allen key, just enough that the filament is transported reliably without slipping or chipping. Turn the screw clockwise to increase the preload and counterclockwise to decrease it.

To test material transport efficiency run the Prime Extruders wizard and readjust if necessary.

INFO

Be gentle, too much pressure is counterproductive and will result in chipping filament.

Timing Belt Tension

The Tension of the X-axis and both Y-axis timing belts can be checked by measuring the resonance frequency when plucked like a guitar string.

- Activate the build chamber preheating and wait until the 3D printer has reached its operating temperature (70 °C for printing ABS).

- Then pluck the longest free hanging section of a belt and measure the oscillation with a frequency meter.

Make sure to be as close to the belt as possible with the microphone of your device. - Adjust by rotating the knurled thumb-wheels on each belt tensioner until a frequency of about 60 Hz (+/-5 Hz) is met.

- Repeat this procedure for all belts.

Backlash calibration

At delivery, the RepRap Industrial's mechanical axes backlash is calibrated so that printing circular holes and cylinders happens within the stated tolerances and exactly round. Loosely printed infill and support lines (e.g. raft) running diagonally along the print bed appear evenly spaced and parallel.

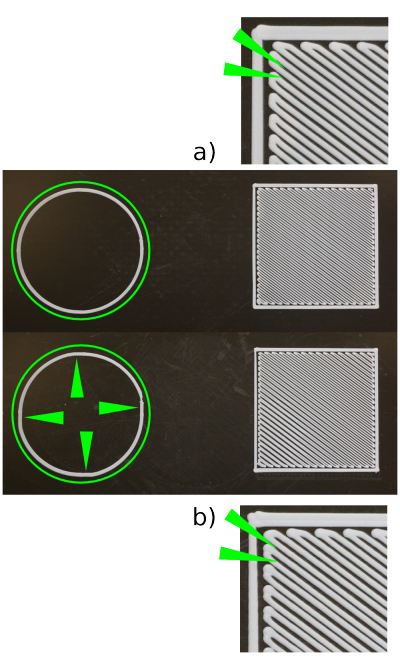

If you find that circular structures are printed out of round or diagonal, parallel lines are printed in pairs (see adjacent image), calibration to compensate for mechanical backlash must be done in the way described below.

Required tools

Beginning with RepRapOnRails version 1.3.0, a new wizard is used to automatically measure and store the backlash values of X- and Y-axis much faster and still more reliably. The procedure described in the following will then be obsolete.

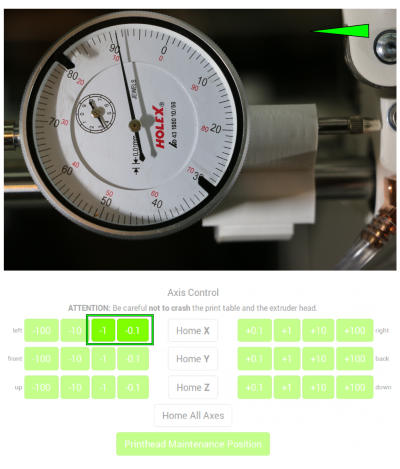

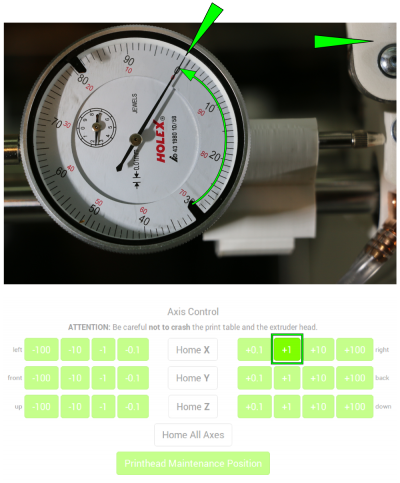

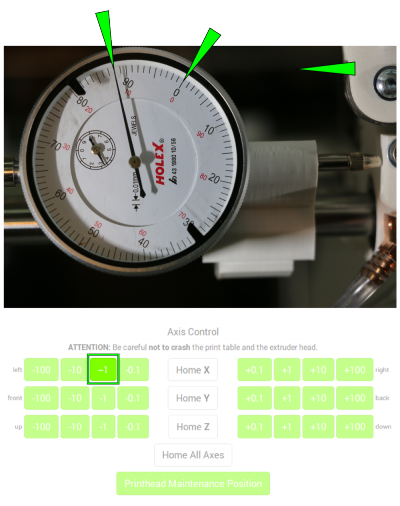

- dial gage (reading accuracy 0.01 mm)

Calibrating

To calibrate the backlash compensation:

INFO

Switch off the preheating and let the 3D printer cool down to room temperature before starting the calibration. Measuring at operating temperature will falsify the results due to the temperature sensitivity of the dial gage.

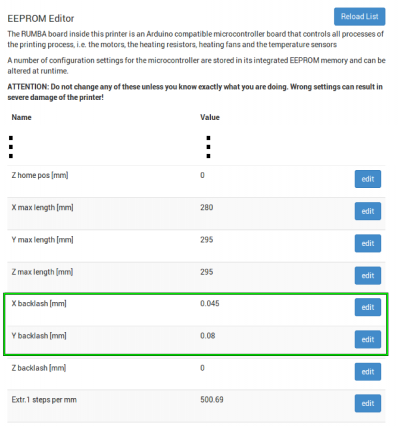

- Open the web interface, choose the Setup menu and scroll down to the EPROM editor.

- Search the values

X backlash [mm]

Y backlash [mm]

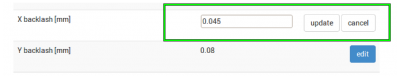

- Click [edit] to activate the respective text field.

- Set the value to

0.000. - Click [update] to accept the value.

- Do this for the other axis.

- Open the Manual Control menu at your RepRap Industrial.

- Move the extruder head to the [Maintenance Position] via the respective touch button.

NOTICE

For the next steps:

Only move the print head via the touch buttons at the touchscreen.

Make sure that you do not move the print head more than 0.1 to 1 mm in negative direction after touching the dial gage's measuring tip.

Otherwise you might damage the 3D printer or the dial gage.

- Carefully move the print head in negative (left) direction against the dial gage measuring tip until you are sure that moving in each direction will effect a readout.

- Move the print head 1 mm into positive (right) direction. Now the timing belt is tensioned and at zero play.

- Zero the dial gage.

- Now move the print head 1 mm into negative direction again.

- Read the measured value:

If the value is <1 mm, backlash is not or too little compensated.

Calculate the necessary compensation by subtracting the value from 1 mm.

Example:

measured value = 0.88 mm

required backlash compensation:

1.00 mm - 0.88 mm = 0.12 mm.

- Enter the calculated value in the web interface's Setup menu for X-axis backlash as described above.

- Remove the dial gage, install it at the Y-axis and repeat the procedure to measure the Y-axis backlash.

Limit values

If the measured value exceeds

0.2 mm in X-direction and/or

0.3 mm in Y-direction

a mechanical fault is the reason for the inaccuracy, most probably a loosened pulley. In this case calibration will effect no significant improvement.

Contact our technical support.

Repositioning and refastening the Z-axis clamp collar

During transport or set up verberation may lead to loosening of set screws. If this happens at the upper clamp collar of the Z-spindle, the initial Z-positioning of a print job becomes inaccurate although the leveling seems OK because the spindle's mechanical backlash will then avert exact positioning only during minimal lifting moves. You will find that the first layer will not stick to the print bed as if it was leveled too high.

In this case the clamp collar must be repositioned and the set screw must be refastened.

Required tools

- Allen key #2.5

Testing and repositioning the clamp collars

DANGER OF BURNING!

Depending on the printed material components of the 3D printer may hold temperatures up to 300°C (572°F) immediately after a print job.

To avoid burning injuries:

- Switch off the preheating and wait until the 3D printer has cooled down to approximately 50°C (122°F).

- Check the current temperature at the display.

NOTICE

Lifting the print table at the front end may damage the Z-elevator assembly and the spindle. Also, leverage effects might effect a false impression of alleged play.

Lifting the print table at the front end may damage the Z-elevator assembly and the spindle. Also, leverage effects might effect a false impression of alleged play.

Grab the print table at the Z-elevator near the bearings when trying to lift it.

Make sure that you do not damage the Z-limit switch.

To test if the clamp collar has come loose, carefully try to lift the print table and observe the Z-drive pulley.

If the pulleys moves up and down, the clamp collar must be repositioned and the set screws refastened.

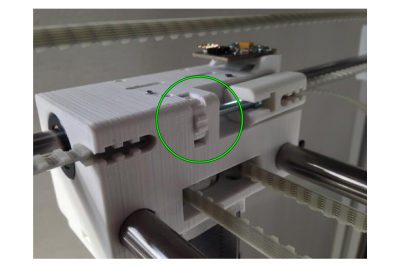

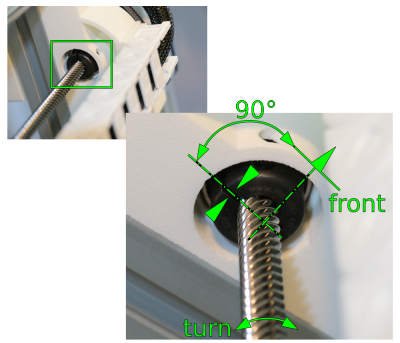

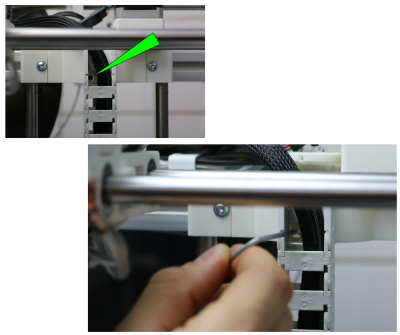

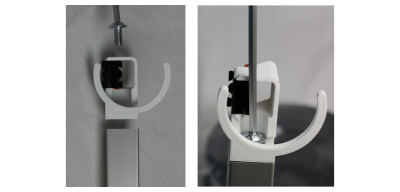

To reposition the clamp collar:

- Carefully turn the spindle of the Z-drive manually so that the recess of the clamp collar points left.

- Loosen the set screw through the access bore in the carriage.

Wiper assembly and installation

If you have ordered the Wiper Upgrade Kit, it comes partly preassembled and must be completed prior to installation in the 3D printer.

DANGER OF BURNING

Depending on the set build chamber temperature internal components of the 3D printer may reach temperatures up to 70 °C and may cause burning injuries when touched.

Shut down the 3D printer and let it cool down before starting to work on it.

Required tools

- #2.5 Allen wrench

- #5 Allen wrench

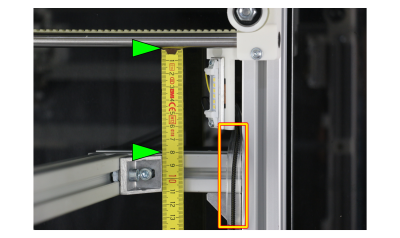

- Folding meter stick

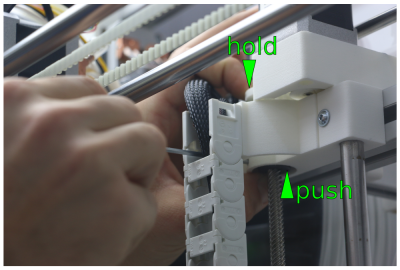

Assembly step 1: bracket and mounting arm

First assemble the bracket with the mounting arm:

- Align the bracket's front side with the mounting arm's groove. The wiper lip must later face the print bed.

- Fasten the bracket to the mounting arm with the M8x16 flat head screw.

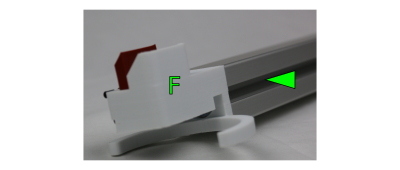

Assembly step 2: Mounting the wiper in the 3D printer

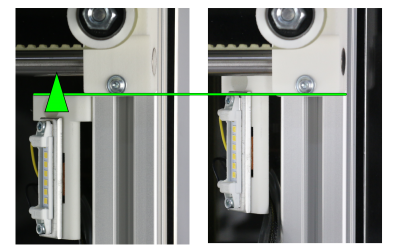

First, the right LED in the build chamber must be moved a few centimeters up to make space for the wiper.

- Loosen the LED's M4x10 fixing screw and push up so that the lower edge of the fastening head is approximately level with the lower edge of the belt idler pulley mount.

- Retighten the fixing screw.

- Carefully pull up a little extra of the supply lines to make space for the mounting arm.

NOTICE

Do not try to hide the LED's supply lines in the groove of the frame. This may lead to damage since the hammerhead nut of the mounting arm must be fastened in the frame groove.

- Position the mounting arm behind the LED's supply lines in a height of 80±2mm below the shaft.

- Fix the mounting arm to the frame by tightening the M6x14 hexagon socket screw.

INFO

For some early deliveries of hardware revision 1.3.0 it may be necessary to remove the upmost zip tie socket. Therefore cut the zip tie with a pair of pliers and loosen the socket with a suitable tool (e.g. screwdriver).

- Insert the excess retainer into the bracket.

Upgrading to 400°C

In case you ordered the 400°C upgrade kit and are looking for the assembly instructions: these are currently only available as PDF download in German language. The English version will soon be available here.

ht400_anschliessen_de_201509.pdf

Electronic components, software and slicing

Download latest Slic3r Configuration Profiles

To allow for always up-to-date Slic3r configuration profiles, the provided config-files were removed from the touchscreen controller system into a separate online repository. As shown on the “First Steps” tab of the web interface, these can now be downloaded from https://github.com/kuehlingkuehling/RepRap-Industrial-Slic3r-profiles/releases in their latest version.

Exchanging BeagleBone Black SD card

In case an update of the operating system of the BeagleBone Black, the touchscreen or the firmware is required, Kühling&Kühling offer update files at http://docs.kuehlingkuehling.de/. Subscribers will be informed via newsletter, for all other users we recommend to regularly check the blog (http://kuehlingkuehling.de/) or the documentation for updates.

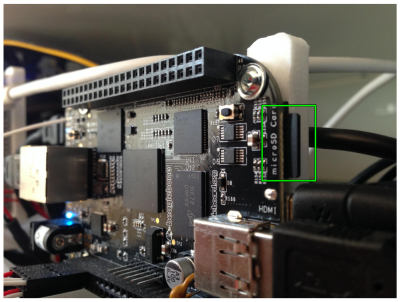

The Micro-SD card in the BeagleBone Black always contains all data necessary to run the operating system as a stand-alone unit, which means that you do not have to overwrite the current operating system but can use a second SD card to replace the original one. This is for safety reasons if something should go wrong during the updating process and you need to quickly restore a functional system.

Updating procedure

- Finish all print jobs and turn the operating system off via the touchscreen ([Shut-down] button).

- Let the 3D printer cool down.

- Toggle the main switch at the back off the apparatus to <0> (OFF) and remove the power supply cable.

- Remove the left side cover of the electronics enclosure (removal procedure as described here).

- Carefully remove the SD card deeper from its slot at the right side of the BeagleBone (pos. 3). The card has a “push and release” removal mechanism.

- Insert the new SD card into the BeagleBone.

- Reinstall the side cover of the electronic enclosure.

- Plug in the power supply cable.

- Switch the 3D printer on by toggling the main switch to <I> (ON).

After the start-up sequence has finished, the RepRap Industrial is now running with the updated operating system.

Update Arduino Firmware

The following description applies only in case you have contacted the Kühling&Kühling Support and have been asked to update the firmware of the RUMBA microcontroller board to solve a specific problem.

Follow these steps to update the firmware:

- Make sure the printer is up and running and accessible via ethernet through the web interface.

- Open the web interface of your printer from your computer and switch to the “Setup” tab. Here you find an “Arduino Firmware Upload” form.

- Select the .hex firmware file you would like to install and upload it to your printer through this form.

- Tap the [Shutdown] button on the touch screen to power down the printer.

- After the screen has gone black and the power-on button light has dimmed, shutdown is finished.

- Now push the power button to boot up the system again. During boot-up the system will program the microcontroller board with the provided firmware file.

When the touchscreen controller is loaded again, check the Log for the line

"avrdude done. Thank you."

This indicates a successful reprogramming of the micro-controller's RUMBA board.

Before using the printer, still in the Log tab on the touchscreen, send the following two commands to the printer:

M502 M500

INFO

The boot sequence may take longer than usual due to the programming routine.

Reflash USB-to-Serial chip firmware on RUMBA board

Symptoms

After booting the RepRap Industrial, the status message on the touchscreen reads “Offline”. The log shows lines like

Connecting to RepRap Controller... ERROR: Cannot send command - RepRap Controller not online! ERROR: Could not connect to RepRap Controller - no port defined!

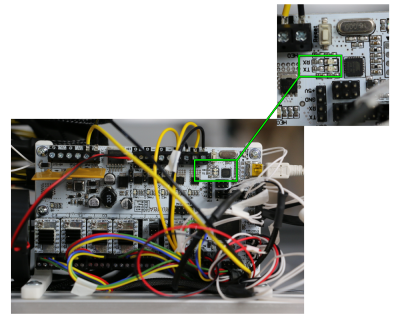

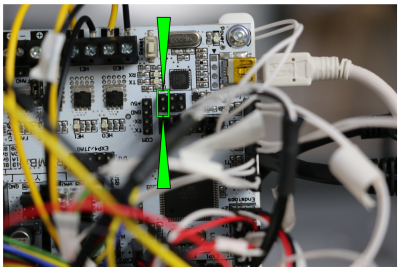

On the RUMBA boards inside the electronics enclusure (see here), the pair of LEDs located nearest to the USB connector (tagged “TX” and “RX”) are flashing alternately all the time

Solution

For some reason yet unknown, the USB-to-Serial chip on the RUMBA board may very rarely either loose or corrupt its firmware and enter DFU mode (firmware programming mode), which is indicated by the alternately flashing TX/RX LEDs. The manufacturer of the boards - Reprapdiscount - provided a solution to this. Chances are high that this can be resolved on-site by carrying out the following steps.

Preparation

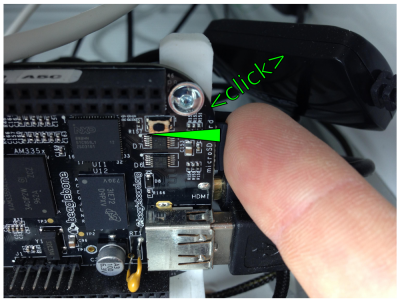

First, the USB-to-Serial chip's programming mode has to be activated. Therefore:

- Switch off the power supply unit (toggle main switch to <0>).

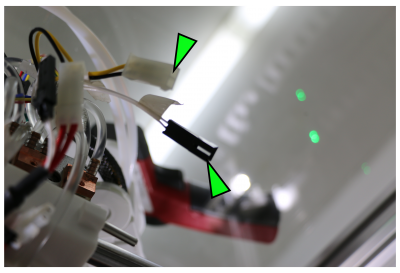

- Bridge the to pins indicated in the adjacent picture with a jumper.

- Switch on the power supply unit and wait until the BeagleBone BLACK has fully booted the operating system.

- Pull the jumper off the pins. The TX/RX LEDs start flashing alternately again which this time means that the USB-to-Serial chip is ready for programming.

Software re-installation

Download all necessary files packed in one archive:

Upload this archive to the BeagleBone Black linux computer inside the RepRap Industrial via sFTP protocol:

Protocol:

sFTP

Host:rriXXXXXXXXXXXX(see Setup --> Backend-URL on the touchscreen) or the printers IP address (if known)

User: kiosk

Password: eight-digit combination from the serial number at the back of the device. Take the first two four-digit blocks -XX-AAAA-BBBB-CCCC-YYYYbecomes anAAAABBBBpassword.

Target directory:/home/kioskConnect to the BeagleBone Black via SSH command line

Protocol:

SSH(command line)

Host:rriXXXXXXXXXXXX(see Setup --> Backend-URL on the touchscreen) or the printers IP address (if known)

User: kiosk

Password: eight-digit combination from the serial number at the back of the device. Take the first two four-digit blocks -XX-AAAA-BBBB-CCCC-YYYYbecomes anAAAABBBBpassword.Extract the files from the previously uploaded archive

tar xzvf ./rumba_usb-to-serial_reflash.tar.gz

Install the “dfu-programmer” software package. Use your SSH password for sudo access.

sudo dpkg --install ./dfu-programmer_0.6.1-1_armhf.deb

Reprogram the USB-to-Serial chip

sudo dfu-programmer atmega16u2 flash ./RRD-RUMBA_ATmega16U2_USB2Serial.hex

Which should be confirmed with the following message if successful:

Validating... 4642 bytes used (37.78%)

If you get this error message, the chip was not properly set into DFU mode or may be more permanently damaged - please contact Kühling&Kühling technical support for further help:

dfu-programmer: no device present.

Shutdown the linux system

sudo shutdown -h now

Switch OFF the power supply mains switch at the back of the machine. Wait at least 10 sec.

Switch ON the power supply mains switch - the RepRap Industrial should boot up again as usual.

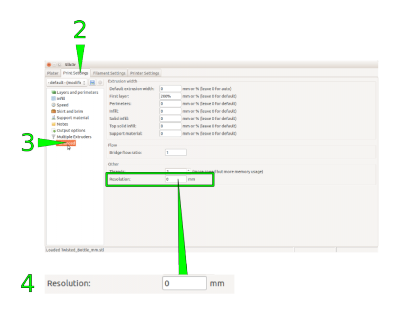

Increasing the minimum detail resolution of the Slic3r

- Open your Slic3r in “Expert” mode.

- Open the “Print Settings” tab.

- Choose “Advanced”.

- Type the required resolution into the input field “Resolution” in the “Other” frame. We recommended setting the resolution to a value of

0.05.

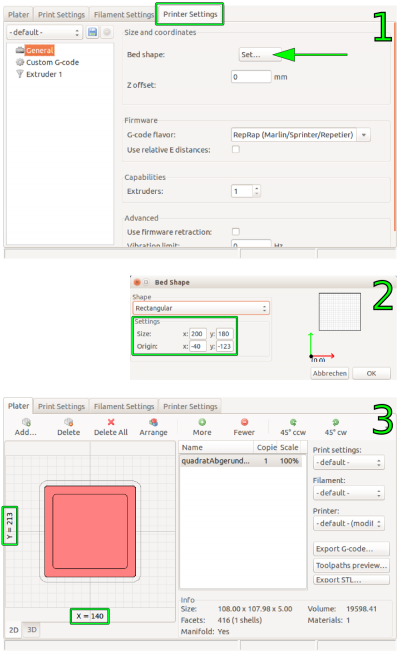

Print bed size settings for different hardware and Slic3r versions

Starting with Slic3r v1.2.0-experimental (issued in August 2014) and its customizable bed shape the origin of the print bed has moved from the center to the bottom left corner, which means alteration of the tool center point is needed.

The 3D printer's position of the print bed origin depends on the firmware version of your RepRap Industrial 3D printer.

INFO

All settings stated below are for control and troubleshooting purposes. Normally, these values are considered in the slicing profiles provided for download at the Kühling&Kühling GitHub repository, so that no additional adjustment should be necessary during normal operation.

The following settings apply:

| 3D Printer hardware revision¹ | Slic3r version | Firmware status | Settings (Scli3r ⇒ Printer Settings ⇒ General ⇒ Size and coordinates) |

|---|---|---|---|

| 1.0.0 | ≤ 1.1.7 | delivery condition | Bed size: x = 200 mm; y = 180 mmPrint center: x = 140 mm; y = 213 mm |

| Repetier-Firmware v0.91-rri1.0.0-03 | Bed size: x = 200 mm; y = 180 mmPrint center: x = 100 mm; y = 90 mm |

||

| 1.0.0 | 1.2.0 and higher | delivery condition | Bed shape ⇒ [Set…] ⇒ Size: x = 200 mm; y = 180 mmOrigin: x = -40 mm; y = -123 mm |

| Repetier-Firmware v0.91-rri1.0.0-03 | Bed shape ⇒ [Set…] ⇒ Size: x = 200 mm; y =180 mmOrigin: x = 0 mm; y = 0 mm |

||

| 1.1.0 | ≤ 1.1.7 | delivery condition | Bed size: x = 200 mm; y = 180 mmPrint center: x = 100 mm; y = 90 mm |

| 1.1.0 | 1.2.0 and higher | delivery condition | Bed shape ⇒ [Set…] ⇒ Size: x = 200 mm; y = 180 mmOrigin: x = 0 mm; y = 0 mm |

¹ To find the valid hardware revision check the type plate at the 3D printer's rear bottom cover.

Example: Print bed settings for Slic3r v1.2.0 and RepRap Industrial v1.0.0